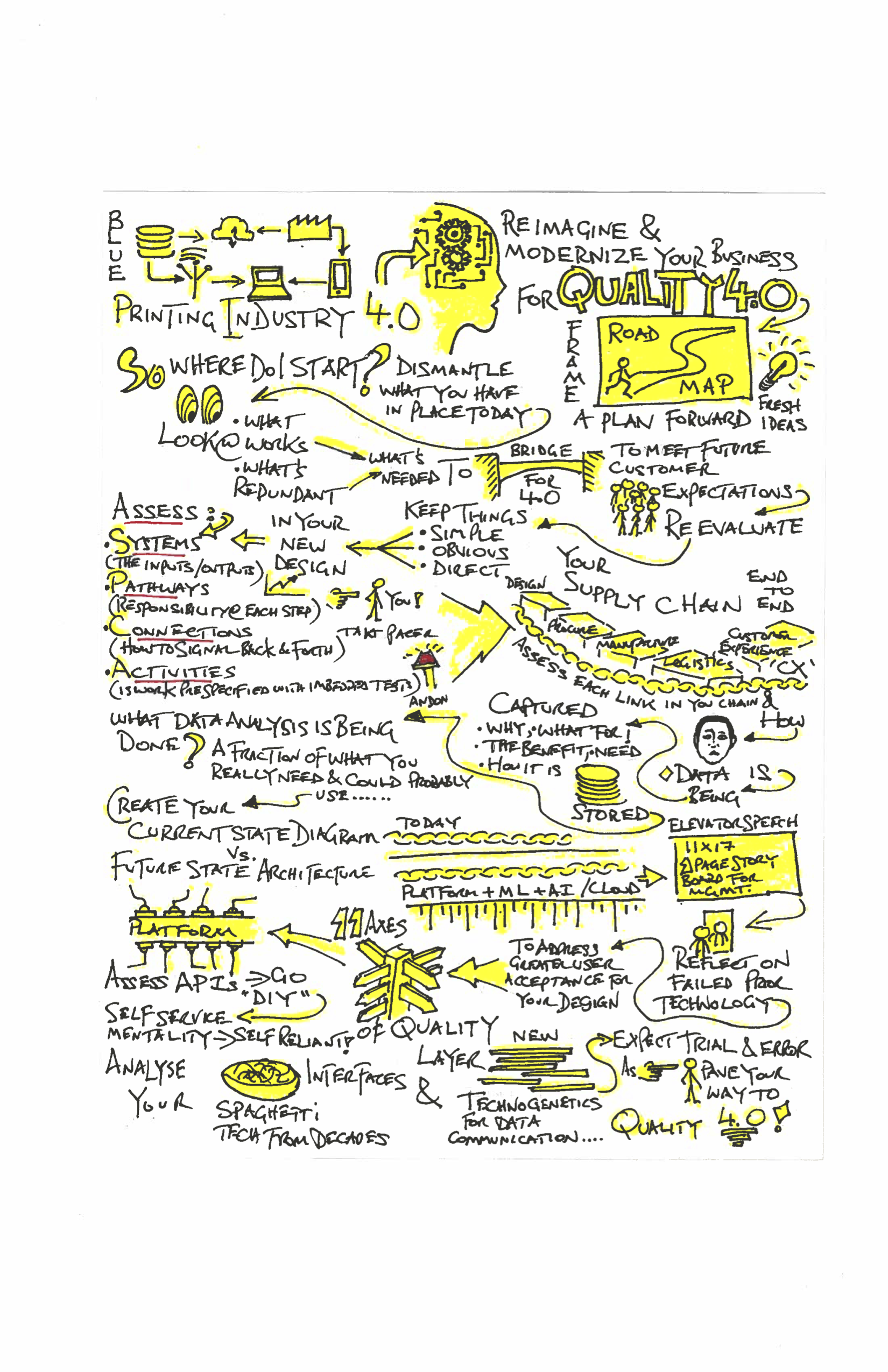

As I argued last month, businesses today need to evolve their industry 4.0 blueprints. They will need to map out their approaches to tackling the modernization of quality in their business realms; which involves creating and sharing their Quality 4.0 Road Map so that it will be operational by 2025.

This necessary evolution will not be an easy task. Few businesses view quality the same way across the different sectors of their industries today, since customer expectations and perceptions of value vary widely depending on the product or service being delivered. A one-size fits all approach will not necessary work, forcing everyone to reimagine quality for tomorrow.

Be prepared to dismantle what you have in place today when evolving to Industry 4.0.This calls for you to dismantle what you have in place today, critically assess what is actually working and what’s becoming potentially redundant in Industry 4.0; and then determine what quality must do to achieve this next level of performance that your customers will value and expect.

Such an analysis will require fundamental rethinking of everything you do, and will benefit enormously from lean thinking and practice. You will need to keep things simple, obvious and direct as you reimagine how you create and deliver value. I’d like to share several techniques that I learned from lean work for the BAMA organization, a group of Toyota component manufacturers who through their organization taught key lean tools & techniques in their popular TPS for Executives workshops for lean advocates and practitioners I have often revisited to use.

This work taught me the value of applying SPCA, an exercise in which we categorized work as: System – what are the inputs and outputs that need to be measured, Pathway – who is responsible at every point in your processes, Connection – how do you signal back and forth, and Activity – is the work tightly pre-specified with imbedded tests to indicate in and out of control conditions.

Tap into lean thinking and practice when fundamentally rethinking everything you do. Understanding SPCA will help you connect and complement the manipulation of real-time process monitoring, coupled with data collection mechanisms and analytical evaluation tools using algorithms and AI to help your business prevent and or predict the likelihood of failures, or events in the quality setup of tomorrow that can dissatisfy your customer, so you can work to prevent these with new technologies evolved specifically for quality application.

Start by Mapping Your Supply Chain

As a starting point, I recommend that you map out your complete existing supply chain, going link by link from product development all the way through to shipping the goods out the door. At each link in your current supply chain, assess what data is being (or should be) captured. What is the need for and the benefit of this work. How is it captured, stored and retrieved today? How is it being analyzed? And what do you do with the analysis? Be uncompromising in gauging whether you are currently tapping into this data in a useful manner.

Then you should explore whether the technology you are using today is capable of providing the information you will need for tomorrow. Is what you need beyond the capability of the existing hardware or software in use today by your business?

This is where the onset of better data analytics capabilities in your business, and AI and ML should be potentially harnessed to see if you need an iterative upgrade of what you have now—to evolve new solutions for your Quality 4.0 roadmap of tomorrow.

I suggest that you map out your alternative options at each link in your current supply chain setup. Quite often I have created a current state vs. future state diagram of the technologies in place using a 11 by 17 piece of paper. Directly across the top of the paper I map out current state, then directly below that I create the future state improved version. So, you can then directly narrate the comparison with senior management quickly and simplistically, and not lose them in a detailed power point deck alternative explanation that they may struggle to absorb or hold their attention for buy-in during a discussion.

For those who wish to get into the weeds on the above, I strongly recommend you look at using insights like the 11 Axes of Quality 4.0 Gartner Framework, which will help you ‘think’ and reflect before making concrete steps down the path which might be unique to your business model and 4.0 blueprint design.

Get Clarity on Key Elements Such as Your Common Platform

Always keep key lean principles such as clarifying and simplifying the work in mind. You will need to get clarity and make decisions on a number of key elements. Choosing a common platform to connect all your revamped or new systems and applications is key. Integrating, the inputs and outputs from all these supply chain links in your value chain that you have assessed is another important challenge. As is ensuring that the API’s (application programming interfaces) can talk across the platform you have selected to hook everything up together within.

When choosing your platform, here’s one key piece of advice I’ve learned from experience: pick a platform that is not reliant on your IT function to necessarily build all the applications and hookups for you. Pick something that you can customize, using your own team or systems engineers to adapt. Why? All too often, local IT in your business builds everything, and you become a prisoner in their priority queue competing for time and attention. While your business IT should control the overall governance from a security and privacy perspective for your platform, proceed with a self-service mentality, which is to say: don’t?be?afraid?to buy into solutions or design and develop what you need within your groups control.

Always keep basic lean principles in mind—such as clarify and simplify the work wherever possible. Today the number of interfaces that a typical employee may have to potentially navigate and use across an enterprise probably exceeds 100 touch points. One objective with a lean approach to Quality 4.0 should be to simplify the bowl of spaghetti we have created over decades, creating a flatter technology platform with fewer interfaces.

As I mentioned toward the start of this article it is important to harness lean thinking and lean practices to facilitate this simplification of the current condition activities of quality today in your business, in order to reach the improved future state targeted condition by 2025, using your developed quality 4.0 roadmap.

I have visualized the key ideas in the following illustration:

Good post, Having the proper knowledge of Quality 4.0 can make things easier. To make things easier a Quality 4.0 awareness training will help you.