Many lean thinkers are reflecting on the implications of what is being referred to as Industry 4.0, a term that loosely refers to the accelerating digitization of virtually all work. They are asking the essential question: What part will or should lean play in this space?

It seems clear to me that technology advancements will make many people redundant, and that the technologies we associate with Industry 4.0 will shape a very different picture of our world in the years to come. We will transition increasingly to virtual operating systems with enhanced automated manufacturing footprints, and artificial intelligence (AI) dictating what to do and what not to do. These changes will fundamentally shift the way we think about how work should be done and color our thoughts about how we should make decisions.

Several years ago, I wrote a Post about the influence of AI & the IOT and would like to revisit this topic today. I remain as convinced as ever that lean offers many relevant lessons for this great transition, which is happening at lightning speed all around us. This revolution entails many rapid small yet world-changing iterations occurring one by one, so quickly that they are not all being noticed.

As a lean thinker, I strongly believe that we must step up and take the wheel—to be the drivers of technological change and not the backseat passengers as we evolve to the next best thing.

I work in the e-commerce space, which relies greatly on big tech to lead the way. It’s frightening to see the potential for human activity to become replaced by technology. It’s also scary to see how the surge of remote work sparked by the pandemic has emptied buildings of people and increased the role of some form of evolved AI technology doing a portion, if not all, of work that was once done by people.

Lean thinkers are potential strategic influencers who can and must press folks to think about how we strip out complexity in the tasks and systems now and in the future. They must explore how we connect applications and current complex systems to make it easier for folks to navigate the technology explosion at hand. They should investigate how we organize and structure the evolving communication architecture.

I have seen folks drown in data and suffer paralysis in response to systems churning out far too much information about key decisions to make. Here, lean thinkers can lead management in properly framing the business problem they are trying to solve, using the ‘tech’ in a dynamic way. They can clarify what platform the technology should sit on, ensuring that the applications being hooked up can interface without creating more complexity than what already may exist. This can clarify where the decision-making points would be best served, with humans—not algorithms or AI—making the final call.

Lean thinkers can remind leaders that we should not become the slaves to technology, and show everyone how to shape and adapt technology to serve us for the greater good (not solely on profits). This view may not be welcomed by all. I believe, however, that businesses that want to grow and be sustained for decades to come will use technology to enhance its people-driven problem-solving capability.

I will concede that this is a tricky endeavor to undertake—but one to embark on regardless. The benefits of lean in this emerging world of Industry 4.0 will become increasingly clear with each passing day.

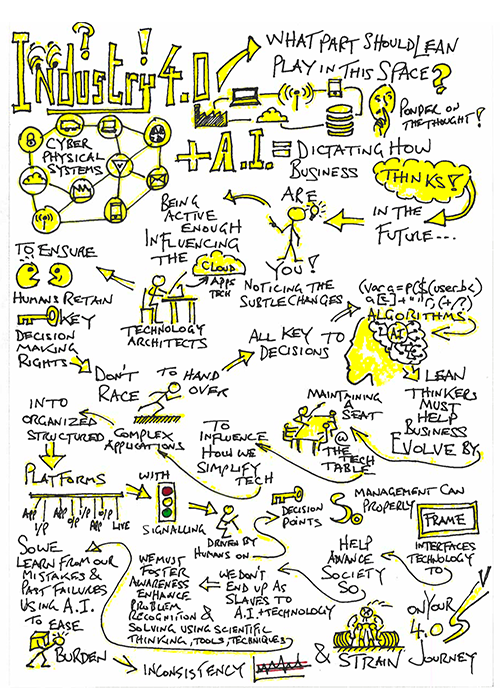

I have illustrated these ideas in the following sketch:

The Future of People at Work Symposium

Collaborating on the Challenges Ahead.