“There is a fundamentally better way to think about, and more importantly, to execute product development,” says Jim Morgan, co-author with Jeff Liker of Designing the Future: How Ford, Toyota, and Other World-class Organizations Use Lean Product Development to Drive Innovation and Transform Their Results. This 2019 book shares a lean development framework that any company can use to design much better products and services, not to mention an improved future for themselves.

Since its release this book has generated a loyal following and has seeded a wealth of useful content, much of which can be found in the LEI archives. The main promise of the book, for example, can be found in this Q&A between Morgan and Chet Marchwinski. “Our goal is to help organizations improve their product and process capability,” shares Morgan. “Whether you are designing a physical product, a servicer, or even a clinical process it is one of the most important activities an organization can engage in.”

He elaborates on this by saying:

“When you develop new products, you not only have the opportunity to create differentiating innovation, but you’re also having a major impact on your operating costs and your quality potential. Great development provides the foundation for excellence in operations. So the decisions that you make during the development process will impact your organization for years to come.”

Morgan and Liker tackle this topic holistically, framing the work as more than just a process, and more than just a set of tools. “Product development is a complex socio-technical system made up of people, processes, and tools—three primary elements that are interdependent,” he says. The authors are careful to offer principles and practices that transcend any one function—that will enable organizations to apply them in all areas.

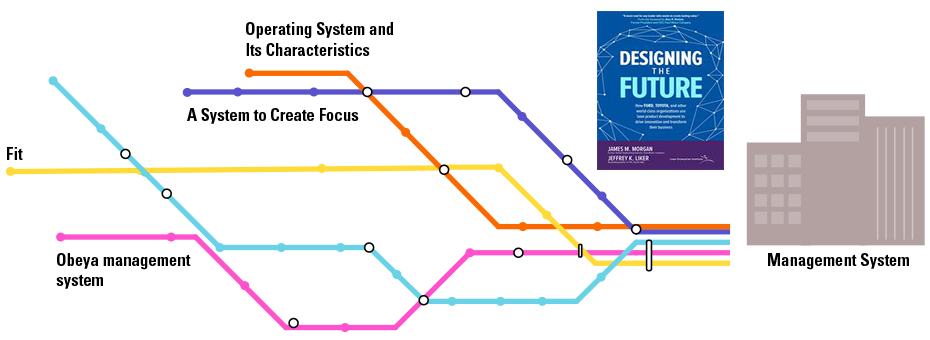

One excellent feature of DTF is its focus on both technical and social aspects of this work. Based on extensive field work at Toyota, Ford, and other organizations, the authors draw from their observations to share robust principles for anyone. Morgan cites a formula called LB times OS equals MS, for example, referring to the idea that a management system (MS) equals leadership behavior (LB) times the operating system (OS). He developed this idea based on working with and learning from Alan Mulally at Ford during its dramatic turnaround.

Worth quoting is this passage in which he details how a comprehensive approach ties together:

“An operating system is made up of the tools, processes, standard work, cadenced activities, and other mechanisms that enable the work to get done. If a leader is the craftsman, then the operating system is his or her collection of tools. But a good operating system is far more than the sum of its parts.

An effective operating system moves an organization toward its objectives in order to accomplish its mission. It creates a cadence of regularly occurring management activities instead of episodic management interventions. It is a single, integrated system, not a hodgepodge of departmental plans that do not hang together. It is transparent, multileveled, and cascades throughout the organization. It establishes objectives, allocates resources, and provides clear, aligned roles and responsibilities in order to deliver the plan. It provides the structure that enables (or inhibits) people to do their work. It knits together and drives critical value-creating activities, such as strategy deployment, continuous improvement, new product delivery, people development and working environment, manufacturing, and supply chain. Finally, the operating system provides its own performance feedback on how you are doing.

An effective operating system helps brings strategy to life. It synchronizes critical activities, enables the organization to respond quickly to a changing environment, and allows plans and teams to move together. And when executed with discipline and coupled with effective leadership behaviors, it provides a tremendous competitive advantage for any organization.”

Leading a strong culture of lean process and product development requires mindful managers, and this book has a lot to teach in this area. Morgan’s Are You Building High-Performing Teams? explains why this matters so much, and he shares a checklist that helps to do so:

- Create a mutual commitment between: the organization that supports, recognizes, and rewards individuals; and the individuals who commit to doing the best possible work for the organization and its customers.

- Develop a clearly defined, deliberate culture for high performance that is consistently reinforced by leadership at all levels.

- Hire people not only on technical credentials but also on fit with the desired culture.

- Develop people from the time they enter the company throughout their careers, using the right mix of professional training and learning at the gemba with a coach.

- Provide ongoing performance feedback in the shortest practical intervals, coupled with constructive guidance on how to improve.

- Support leaders who demonstrate the skills to engage individuals to become a high-performing team.

- Cultivate an environment in which people are continually challenged with the next big opportunity to satisfy and excite customers.

- Foster a supportive organizational structure that strikes a balance between deep development of functional expertise and multifunctional focus on customers.

- Guide downstream functions that are responsible for building and delivering the product or services to become fully engaged as part of the team up front in the development process.

- Create an engaged enterprise that includes all key internal functions and external suppliers of critical components and systems which are enrolled as part of one team.

***********************

The Virtual Lean Learning Experience 2020 (VLX), hosted by the nonprofit Lean Enterprise Institute (LEI), features a two-week immersion into LPPD principles and practices. The theme of the overall event will is Building Resilience with Lean Thinking and Practice. Register and hear from the foremost practitioners and coaches on a range of crucial issues. Jim Morgan will be participating in several activites exanding on LPPD principles–and his book.