Lean management thinking and practice is well-positioned to fix the business turmoil caused by the coronavirus pandemic and other critical looming challenges, according to the two leadoff keynoters at yesterday’s start of the Virtual Lean Learning Experience 2020 (VLX) conference.

Lean management “has always made its dramatic leaps by responding to big challenges, problems, and crises,” said Jim Womack, author, management thinker, and founding CEO of the nonprofit Lean Enterprise Institute (LEI), during an online keynote and Q&A.

He cited the invention of “flow production” in 1914 by lean trailblazer Henry Ford to avoid heavy borrowing. Another example was Toyota’s development of what became lean management in the 1950s and 1960s as a response to cash and quality problems.

The Current Era’s Crisis

Womack said the “big crisis” of the 21st century for lean practitioners to solve is climate change. “That’s not meant as a political statement. The world is warming up and some places are getting wetter and some places are getting drier.” He said it is clear that a lot of “adjustment” is necessary.

Because lean methods create more value with higher quality and lower costs by removing wasted time, money, space, and human effort from business processes, the freed-up resources can be used to pay for the adjustments such as solving environmental problems, Womack suggested.

Those same waste-removing techniques are ideally suited to find the best ways of transporting and distributing coronavirus vaccines. Womack called vaccine transportation and distribution “the next wave” in fighting the pandemic. Another problem to solve is improving healthcare processes to deliver better long-term care to coronavirus patients.

Six Principles for Lean Innovation

During his keynote and Q&A, Jim Morgan, author, former product development executive at Ford, and most recently COO of startup Rivian, urged attendees to move beyond traditional innovation methods to lean product and process development (LPPD).

Traditional development tends to develop new products and services in isolation or relies on a lone-genius approach. The LPPD framework combines people, processes, and tools to create new products and services in tandem with the value streams for delivering them to customers. As a result, LPPD not only delivers a succession of profitable products but better futures for companies, employees, suppliers, and stakeholders.

Morgan said six principles guide LPPD:

- Understand before you execute

- Be aware of customer and context,

- Identify knowledge gaps,

- Think in sets and experiment to learn,

- Develop a concept paper for the new product or service.

- It’s a team sport

- Engage people from across the organization,

- Enable teams to communicate, collaborate, coordinate to make timely decisions,

- Be transparent because “you can’t manage a secret.”

- Synchronize workflows

- Coordinate work across functions to reduce time to market,

- Understand how work is actually done across functions and interdependencies.

- Build in learning and knowledge reuse

- Learning and discovery underpin great products and services,

- Build learning into the way work is done.

- Design value streams

- Design every needed step to deliver value beginning during the study period and continuing through the entire development process,

- Compatibility before completion.

- People first

- The development system helps people succeed,

- Inspire don’t intimidate.

In practice, for instance, “people first” means the latest digital technology is deployed not to replace people but “to make information more usable, so people are more effective and successful.”

In Need of Lean Solutions

Besides climate change and the pandemic, Womack identified these other critical challenges in need of lean solutions:

The Challenge of Work

- Lean’s origins are in the touch-labor manufacturing world, but the touch work in the future will be group work rather than individual work (e.g., agile/scrum teams.) What does this mean for lean thinking?

The Challenge of Management

- The term “digital transformation” is everywhere, but what does it mean in practice and for lean?

The Challenge of Software

- Producing and maintaining software (both as a development and a production activity) is the key value-creating work of knowledge workers. What do lean practitioners have to say about efficiently producing high-quality software that actually meets user needs?

The Challenge of Our Origins

- The world sees lean as part of the machine age. How can that be changed to address new realities?

The Challenge of Solutions

- The world increasingly thinks about solutions – bundles of goods and services that solve customer and societal problems. What does the lean community have to say about developing and operating a solution world?

Addressing the challenges will require new lean tools, methods, and mindsets, Womack predicted. But lean is “not theology. It’s not carved in stone. It’s not dogma. It’s not orthodoxy. It’s a continuous experiment. The life of lean; the light of lean is our experiments.”

How to Join the VLX Conference in Process

Womack and Morgan kicked off “Lean Thinking Past, Present, and Future, the first of the conference’s four tracks. The first track continues through Friday, September 18, with online Q&A sessions with the presenters and discussions among attendees.

The tracks, comprised of presentations, panel discussions, online networking, “go-do” challenges, and supplemental resources for download, are delivered for a few hours over a week. Registration remains open for the remaining tracks individually or bundled together:

- Developing the Lean Enterprise — Lessons in Leadership: Manufacturing, healthcare, education, and supply- chain leaders describe how they built resiliency using lean thinking and practice: week of September 28.

- Leading Through Crisis — Advanced practitioners share how lean management helped them meet the challenge of the coronavirus pandemic: week of October 19.

- Designing the Future — Jim Morgan leads a nine-member team of speakers from various sectors describing their lean approaches to innovation: weeks of November 9 and 16.

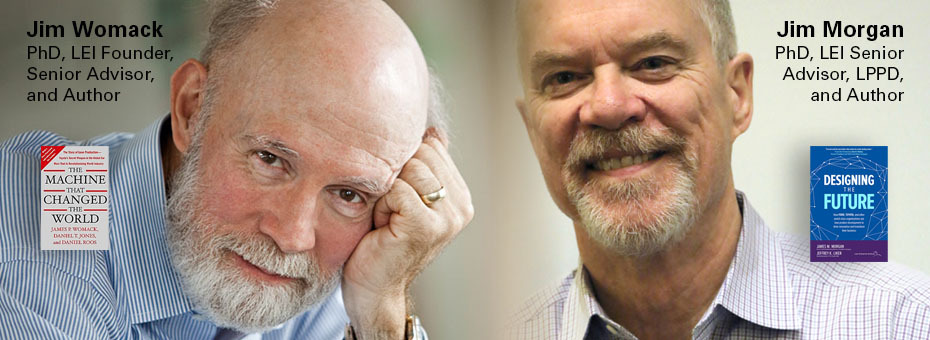

About Jim Womack

For the past 30 years, Jim Womack, PhD, has pioneered our understanding of lean management, a set of ideas and practices designed to create more value for customers while using fewer resources. With coauthor Dan Jones, he wrote a series of award-winning books, including The Machine That Changed the World, Lean Thinking, Seeing the Whole, and Lean Solutions, all of which broke new ground in making lean ideas understandable to a broad audience. His most recent book is Gemba Walks, a collection of eletter essays written after visits to companies over the course of 10 years describing the successful–and not so successful–adoption of lean management. He is the founding CEO of the nonprofit Lean Enterprise Institute, where he currently is a senior advisor.

About Jim Morgan

Jim Morgan, PhD, spent more than 30 years leading engineering and product development efforts at several large companies, including 10 years at Ford Motor Company, where he served as a global engineering director during the greatest product-led business transformation in recent history under former CEO Alan Mulally. Morgan is a hands-on product development leader who can fabricate and weld his own parts. He is coauthor with Jeff Liker of the award-winning The Toyota Product Development System: Integrating People, Process, and Technology. Their most recent book is Designing the Future. A Navy veteran, he currently is the senior advisor for lean product and process development at the nonprofit Lean Enterprise Institute.