With the proliferation of virtual meetings necessary to get work done, while many if not all, of us are isolated at home, we must ensure meetings are productive. After all, a meeting is merely a part of a process to achieve a goal. In part one, I wrote about the importance of using a communication framework, Ho-Ren-So, to determine whether to hold a meeting and, if so, what kind. In this post, I’ll share what I learned from Toyota about how to run a productive meeting.

Read part one: Combat Isolation with Productivity by Using Ho-Ren-So

**********

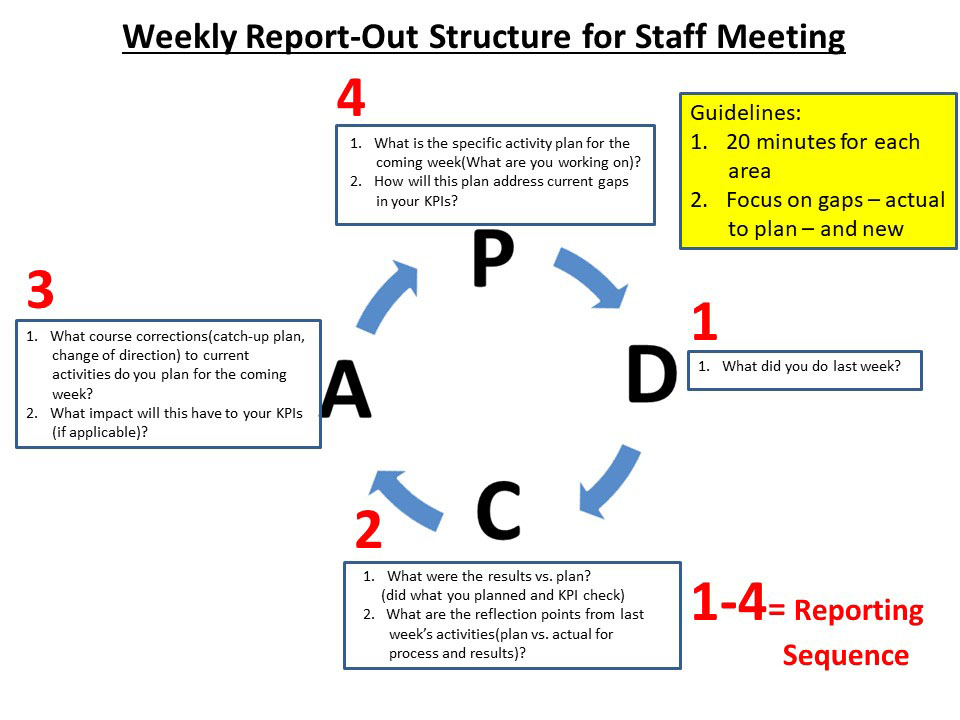

As with many Toyota processes, PDCA is at the core of running a productive meeting or series of meetings. Let me explain practical ways of how that works.

First, as we think about applying PDCA to meetings, it’s essential to keep in mind a few critical points about Lean Thinking and practice:

- We want to drive the authority for problem-solving to the lowest level in the organization. Individuals can solve their own problems with a defined framework.

- We want a mechanism for the Team Member to “pull the andon” when they hit an obstacle, and a meeting can be that mechanism (particularly in a non-operations environment).

- Before we pull the andon, ahead or behind must be clear. Are we on plan or not? The overall project, along with its deadlines and KPIs must be clear (and the meeting is one step in the process).

- We need a structure to clarify responsibility — the more, the better. Yes, we “knowledge workers” tend to buck at too many constraints, but please remember the value and purpose of standardized work. It provides us the freedom to determine our next kaizen and unleash our creativity. Clear responsibility keeps people engaged, productive, and helps us fight isolation — at any time, but especially now.

At Toyota, we used the fundamental structure of PDCA to manage a meeting or series of meetings. Here’s how:

Plan:

- Clarify the purpose of the meeting. How does the meeting contribute to achieving our milestone or business goal?

- Define who should attend and who should provide input.

- Determine the “owner” of the meeting and his/her role.

- Define when the meeting should happen (based on milestones).

- Clarify the length of the meeting, based on the meeting agenda.

- Create an agenda specifying the topics to be addressed.

- Assign a presenter for each topic and indicate the amount of time they’ll have to present.

Agenda Example:

| Executive Leadership Team Meeting

Date: Sept 4, 2019 Purpose: Review Work of Leadership to Accelerate Lean in Our Organization Attendees: Jim Barber (meeting owner), John Caulfield, Lori Steffan

|

Key Points:

- The person solving the problem or proposing the idea should clarify the issue to be discussed by writing it down in a proposal.

- The proposal or other materials should be shared with all attendees in advance of the meeting. Allow at least two days, so they have time to read and prepare questions.

- If we are addressing a problem or reporting-out on progress, what is our KPI? How do we see that we are meeting our goals?

Do:

- Define who leads the meeting – the person who manages the agenda (usually the person who set it up, but not always).

- Clarify who keeps time and ensures the discussion does not run too long on a specific topic (usually the leader of the meeting).

- Identify who presents and how proposals will be presented.

- Assign responsibility for preparing the minutes.

- Clarify the focus of each agenda item.

Key Points:

- Limit the presentation of an idea to 10 minutes to force the effectiveness and efficiency of communication.

- Spend more time on discussion and less on explaining.

- Send meeting attendees the material in advance — this shows respect for the meeting participants. Reading what is sent to you shows mutual respect for others on your team.

- Focus on “abnormality management.” Spend time on items in red – plans that are running behind schedule and therefore need help. This helps us develop a culture of focusing on problems and making people feel comfortable raising issues.

- Clarify the action items at the end of the meeting by determining who will do what by when.

- Compile and send meeting minutes to clarify follow–up responsibility – who will do what by when.

- A key point about minutes: Merely recording what happened at the meeting is not enough. The following format helps:

Meeting Minutes

| Agenda Item | Specific Activity | This Week’s Plan | Follow-up Item | Owner | Support | Deadline |

Check

- Send out minutes as close to the end of the meeting as possible.

- Confirm that tasks that must be completed before the next meeting are assigned, especially if this meeting is part of a series.

- Reflect on the effectiveness of the meeting: Did we meet our plan? Did we stay with our agenda?

Adjust

- Consider whether the structure of the meeting should be changed. Review all the items in Plan above.

- Revise the agenda based on our reflection, updates that are needed, or information to be shared during the next meeting.

- Highlight items that are behind (in red) as a focus area for the upcoming meeting.

Meetings can generally do two things – they can drag us down and bore us, or they can engage us and make us more productive. With all of us sitting through a series of endless virtual meetings these days, we would all feel better if they are more productive. PDCA is a simple structure that helps us conduct meetings and monitor our progress toward our goals and plan targets.