Dear Gemba Coach,

Lean seems like a great tool for the implementation of a company’s environmental and social sustainability strategy in a manufacturing plant. However, I look at many postings about implementing lean and wonder whether I am being too much of an idealist in believing that you can get authentic employee engagement and a “whole-system” approach with lean. What do you think? Can a manufacturer use lean to advance its environmental and social sustainability strategy?

Tough question. To try to answer sincerely, we need to step out of the comfort zone, into the stretch zone and risk falling into the panic zone. Let’s abandon totally the notion that lean is a system of organizing production, and consider the thought that lean is a discipline of learning-by-doing. In other words, close all the lean books and re-open Taiichi Ohno’s writings with a different set of glasses.

A learning-by-doing discipline of what? Well, of increasing value – services divided by total costs – and the total participation (as in, everybody all the time) in increasing value:

- Services: what do we need to offer to sustain the continuity of customer satisfaction?

- Total costs: how can we reduce the total cost of delivering those services?

Ohno’s approach to answering this question is not by looking for the right answer, but by setting a practical, hands-on system, kanban, to uncover misconceptions about both value and costs. In practice:

- Sell one, make one: If customers no longer buy what you sell, and you no longer produce, you have to face the misconception in what you currently propose to them and try to offer something more relevant.

- Kaizen to deliver every kanban at the required takt at the lowest cost: Trying to deliver every kanban exactly on time will force you to face all the usual wastes, starting with overproduction, and shine the light on what needs to improve, as well as the hidden accounting misconceptions that led us to set up work that way in the first place.

Armed with these two lean tools, we can look at the situation differently.

Mental Re-arranging

First, greener products. Customer demand is changing, driven by their own increasing environmental consciousness. They are rarely militant, but they will pick the greener product of two available choices. Demand is also driven by changing regulations and changing insurance policies and so on that influence the accounting of “green-ness.”

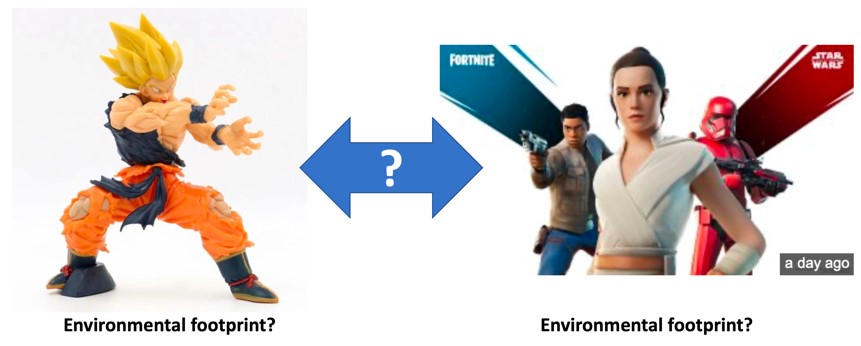

This can involve some serious mental re-arranging. For instance, my kid is transitioning from playing with Lego to playing online with his friends on games such as Fortnite (argh!). He now would rather purchase virtual “skins” (characters to play with inside the game) than physical figurines. As a parent, I realized that I long resisted the idea of buying a virtual gift as opposed to, say, a plastic Son Goku figurine – buying something. Then it hit me that the virtual toy has a much lower material footprint than the figurine (I visualized the presses producing arms and legs in China and then the assembly lines putting the figuring together). Following on that thought, I also realized I had no idea of the environmental cost of holding one more virtual character on Epic Games servers, probably somewhere in Iceland and contributing to global warming. In other words, I have no idea – no idea at all – of the environmental (materials and energy) and social (jobs) accounting of what I am purchasing.

The point is if I follow the “ask for one/buy one” for my kid, I see demand shifting away from physical toys to virtual ones. This is something I need to understand, beyond my knee-jerk reaction of feeling by purchasing digital toys. It is also the opportunity to learn more about the green economies of figurines versus skins.

The first step to improving the environmental footprint of our products is learning more about it.

With this in mind we can take a long hard look at our products and come up with some practical challenges:

- Where can we lighten the product: Fewer parts, thinner parts, less damaging materials without lowering performance?

- Where can we switch energy sources: Fossil fuel to electric, electric to gravity?

When the leader asks herself seriously these questions, she will probably come up with a couple of obvious opportunities, she can then frame clearly for her staff. The Prius concept, for instance, was “normal drive with minimum footprint,” which, bizarrely included minimum noise and minimum visual presence, which is kinda strange for a car (compare the two following images of a Porsche vs. a Prius in the same background)

In one case, the car makes the picture, in the other, the desert – guess which is which.

Universal Wastes

As a writer, I can make the choice to offer solely digital versions of my books in order to reduce the material footprint (paper and printing) of my work. I have to confess that I’ve not made this step yet both for emotional reasons (I started writing because I love books) and because many people still prefer to read on a page rather than a screen. I have, however, killed the idea of producing a paper collection of this column: who needs a printed version of on-line material?

From product to process, we can then look at how to reduce the footprint of making the product. In any manufacturing operations, these obvious wastes can be highlighted:

- Scrap and defectives: How many parts do you throw away before getting a good one after a tool change? How much material do you scrap to cut out a part? In any plant, there are endless opportunities to reduce the material footprint of scrap.

- Plant size: Most plants have been designed at a time where big meant good. Larger plants mean more heating (or cooling) more equipment, more transport – it’s wasteful. In my last visit to Japan, the Daihatsu plant was planning to respond to a rise in demand by building a second plant aiming to produce the same volume with half the surface.

- Equipment size and energy consumption: In japan as well, we can see efforts to replace large, heavy hydraulic machines with smart karakuri devices made by the operators themselves.

- Waste management: Zero landfill material is an obvious target to improve an operation’s footprint, as well as halving water consumption. None of these challenges are easy, but by expressing them clearly, the sum of ideas can achieve wonders.

These are questions we can ask ourselves hands-on in the gemba by wondering: how much material, equipment, and energy does it require to serve every kanban card. We can try to estimate the footprint of a kanban card: to deliver that box of parts we need:

- So much material and consumables

- So much equipment and the energy to power it

- So many square meters and the energy to heat/cool it

Finally, we can also challenge supply chain logistics and make sure that suppliers are located closer to the plant and that trucks are fully utilized to avoid transporting air – which also means taking a hard look at packaging and space standardization in the trucks.

This learning discipline leads us to narrow down choices to a practical first step. For instance, as a writer, I can grit my teeth and move more aggressively with online-only publication. So far, I’ve been following a hybrid route of on-line and print-on-demand and have argued with my publisher to abandon the traditional batch print-and-pulp route.

As a manufacturer, an obvious place to start is the systematic use of karakuri devices. These smart contraptions:

- Reduce considerably the manufacturing footprint

- Are conceived and built by team members in kaizen activities, so involve everyone in coming up with greener solutions for their plant, which is precisely what we try to do

AIO, for instance, is a company set up to teach manufacturing operations across the world how to build their own karakuri devices through kaizen.

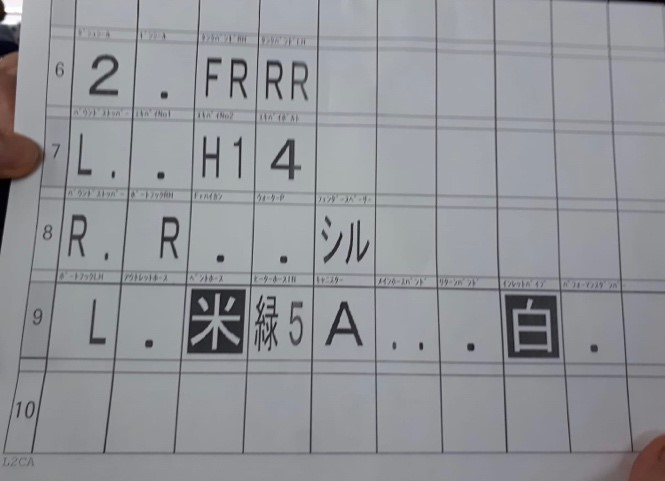

The answer to your question is, I believe, yes. But to get to this yes, we need to change our outlook on lean. Rather than seeing it as a tool to implement manufacturing strategies, we need to look at lean as a learning discipline. First, the leader learns more about greening her products and processes, then she focuses on a concrete thing that can be changed and expresses it in a way that everyone in the company can understand. Then she needs to ask every employee to come up with suggestions and initiatives to make it work, as we do with the karakuri, or ask people to re-use every scrap of paper rather than open a new packet and so on. For instance, this Lexus plant showed us how they re-used car kanbans for writing paper.

To get employee engagement on the “whole system” we need to frame concrete challenges people can get on board with and participate in, and we need to support them to form unexpected company-wide solutions.