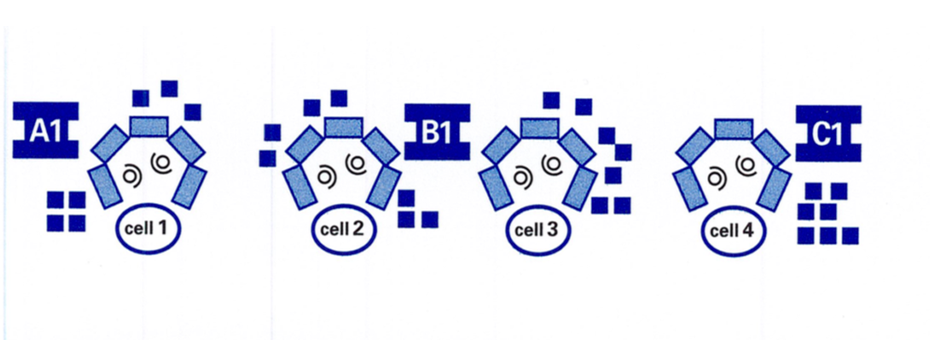

Jeff (assembly) and Josh (machining) run a machine and assembly operation, which sells small engines. They bring in all the raw supplies. The first process machines one critical component used at the start of assembly. This critical component has three varieties. There is a machine dedicated to transform each variety so it is ready for assembly work.

The demand for variety A is 900 per day. Demand for variety B is 600 per day. Demand for variety C is 300 per day. A shift is 480 minutes of work time for machine and assembly. The layout has these three separate machine next to each other in a room that is 100 yards from assembly, with a WIP Pile 30 yards from assembly; and assembly 20 yards from shipping.

The three machines and their cycle times are as follows:

*Machine A= 25 seconds part (5 seconds human (load & unload) and 20 auto time).

*Machine B= 45 seconds part (10 seconds human (5 prep part + 5 load/unload) and 35 auto time).

*Machine C= 90 sec part (10 seconds human (5 prep part, 5 load/unload) and 80 seconds auto time).

One person is assigned to a machine for 1-2 shifts daily.

Machined parts comprise a WIP Pile of 1-2 days before assembly.

Assembly produces in a daily lot size of A, then B, and then C through one shift, plus overtime. It takes 8 minutes to assemble a completed small engine in any one of the three varieties. Assembly uses 38 people and runs at 13 seconds an engine. Output is 98%.

Jeff and Josh report to Karen. Karen has challenged them to free up cash flow and space by rethinking how they schedule Assembly and Machining. Now there is a one day lot size scheduled into each area with two days between them. Karen can see the way forward because of past experience. She does not dare just tell them what to do because they will miss a critical learning opportunity.

Karen’s plant has seven of these types of lines and machine equipment, but she selected the one run by Jeff and Josh since they need a little encouragement now and again.

Karen’s Challenge:

- What lot size is optimal to run through assembly to achieve our goal of 1800 day to open up floor space and free up cash flow?

- How much of each of the three machine varieties do we hold between machine and assembly?

- Do we have the best layout in place now? If not why and what should we do?

- After considering what needs to change, how do we communicate making that change so our team members make it their own idea and implement it?

There may not be a perfect answer, but if you were in the same situation and given that challenge how would you answer Karen?

In addition to Karen’s questions, can you identify any important lean concepts that Josh and Jeff need to brush up on?