Lean Production isn’t just about the factory. It doesn’t even begin there and certainly doesn’t end there. It ends with the customer. Where does it begin? Also with the customer. But that pithy statement (it begins and ends with the customer, kind of like a farm-to-table circular economy mantra) doesn’t mean much. Not because it isn’t true, but because it isn’t helpful. Many statements that are true aren’t necessarily helpful.

More helpful is to recognize that Lean Production begins with addressing this question: What value do you want to provide for a customer in the form of a product or service? As for the term “lean production,” let’s call it lean thinking to highlight the fact that it applies everywhere. You can apply lean thinking to any activity, any endeavor.

What is also helpful is the powerful new book by Jim Morgan and Jeff Liker: Designing the Future (published in partnership by McGraw-Hill Education and the Lean Enterprise Institute). As members of an intense learning group at the University of Michigan over 25 years ago, Jim and Jeff have been studying LPPD for a long time. Jim, in particular, chose to focus on this topic for his dissertation research and later put his money where his mouth was (actually his hands, feet, heart, mind and livelihood where his mouth was) by working for Alan Mulally to make possible the incredible turnaround that Mulally orchestrated at Ford between 2006 and 2014.

Designing The Future lays out a holistic socio-technical system for developing any new product or service that is underpinned by deep principles. Start with study to deeply understand true customer needs and align around how to meet it. Enroll everyone in the clearly defined mission. Identify and fill knowledge or skill gaps between current capabilities and those required to deliver the needed value, learning and building high performance teams. Experiment to learn and improve the development process using methods such as set-based concurrent engineering, discarding ideas and designs that won’t work, while storing failed designs and experiments as reusable knowledge (you will do this all over again!). Underpin the entire process with a Management System comprised of effective and efficient operating sub-systems operated via the right behaviors by leaders and team members. Everyone learns. The team is developed as the product gets developed. That’s important. You will do this all over again.

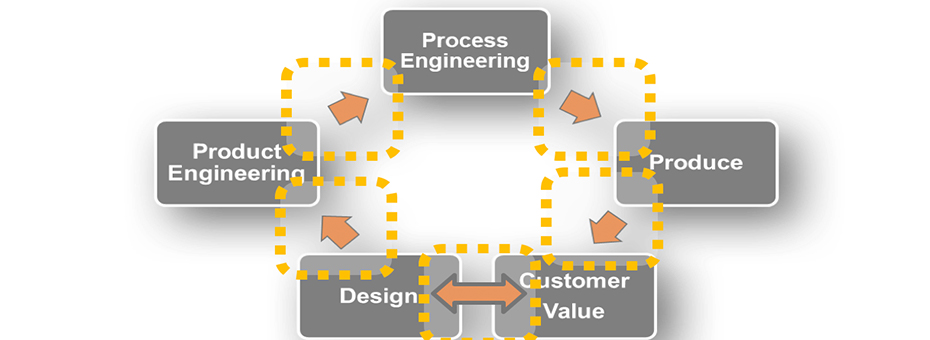

It’s a loop, with closed and open sub-loops, with everything connected. Excellence in any one piece alone will not bring home the bacon. The overall process itself looks something like this (see image above). But, since you will do this all over again (did I already say that?), you want each pass (completion of the loop) to make the organization stronger. After all, since you are designing your future (clever book title), you want to build your capability to realize your design.

In his foreword to Designing the Future, Mulally said, “It is a must read who wants to create lasting value by building not just a great product, but a turbocharged product-creating machine.”

And the only way to create this type of an organization is through extreme transparency and collaboration. An approach Mulally recently described, in a podcast with Jim Morgan, that is “is about loving people – including and appreciating everyone as human beings and caring about them. And the most respectful thing we can do for our teams is to share everything about the plan with everyone.”

Designing the Future contains examples you would expect from the Ford transformation as well as new insights and examples from Toyota, but several unexpected ones as well. Companies are finally (finally!!) turning their lean attention upstream where customer need is grasped, value is defined, and processes developed – all in the interest of creating profitable value streams (see LPPD by Ward and Sobek) for customer delight and enterprise prosperity. Examples include Herman Miller, GE Appliances, Embraer Aerospace, Michigan Medicine (formerly UMHS), Solar Turbine, and oil and gas industry mega-supplier TechnipFMC.

One of my favorites is the story of Schilling Robotics in Davis CA. Inventor and entrepreneur Tyler Schilling, upon witnessing (and participating) in the LPPD initiative at the company he founded and that now controls more than 40% of the ROV market and 95% of the manipulator arms market says: “I had nightmares of my most critical resources around here, inside a PowerPoint program resizing circles, changing fonts and just basically wasting their time. Then I saw what you guys were doing with Obeya. It was a wonderful expression of spending time on substance and as little as possible on form. I especially love attending the obeya meetings; It is a frictionless flow of information that happens in a truly efficient manner. Once a week about 50 people from every function get a supercharged dose of what’s going on. Decisions are made and the team moves on. It brought back the rich communications we had in the old days when we were just a start up.”

To twist a statement Jim made recently, the road to production hell is paved long before the product gets to the factory. Begin laying the pavement to smooth production, customer satisfaction and prosperity for you and your community by learning and applying the principles and practices of LPPD.