Dear Gemba Coach,

I’m part of a team that has been tasked to implement lean tools across the company to drive continuous improvement actions, and yet I see little overall change in our culture. I read about cases where lean works and wonder what we could be doing wrong.

Oh wow … fascinating question. Obviously, I’d have to know a lot more about the context to answer meaningfully, but I can venture a few guesses.

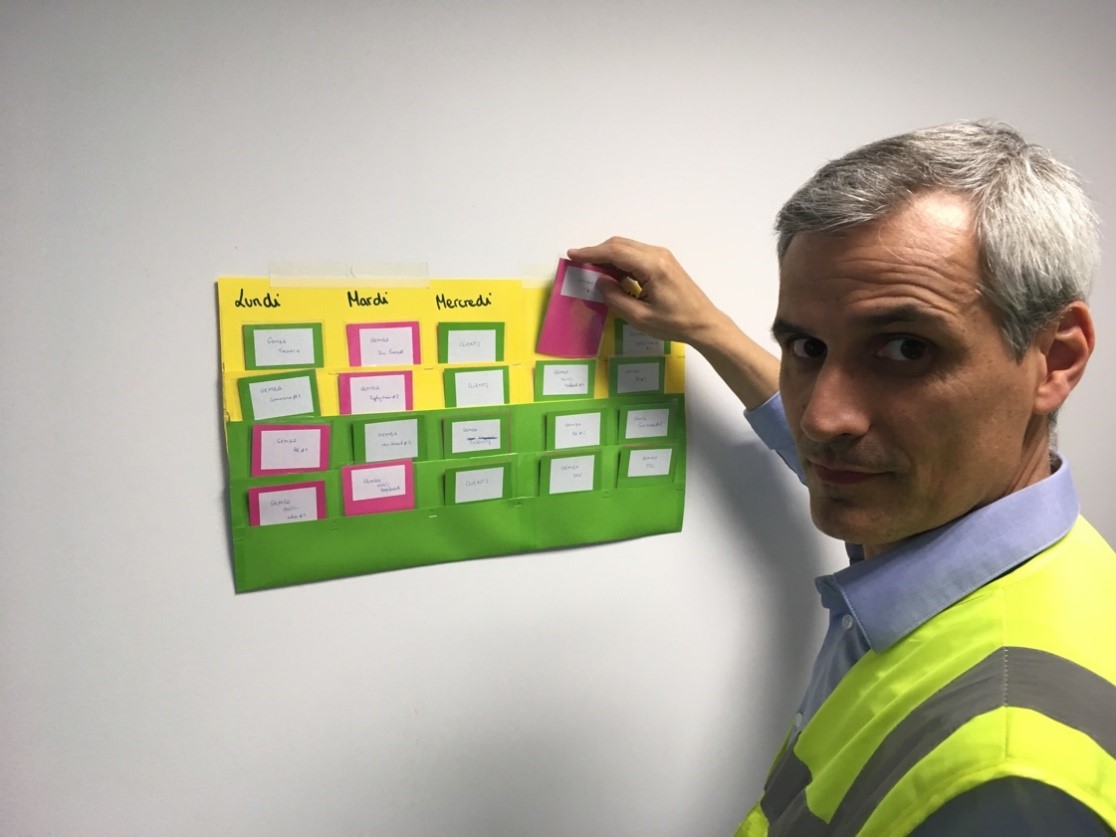

A few days ago, I took a class to visit AIO, a small company that had to reinvent itself when it lost half its business in the terrible years of 2009 and 2010. The CEO then rebuilt the company around lean tools, using lean visualizations as its main management mode. They have kanbans in the sales department to visualize how fast they respond to quotations, in engineering to track the engineering lead-time for every project, in the supply chain to source the components, and in production where the operators also do their own yamazumi to organize the work in bespoke, low quantity orders.

The one point that struck the students was how each person in the company could explain what they did, why they did it, and the impact on customers and other departments in the chain, and what specific improvement point they were working on. That would be the culture change part: the lean tools are not applied to do something to people. The lean tools are there so that every person can orient herself, understand both the purpose of the work and the next step, and work on their own quality improvements.

The other interesting thing about the visit is that in telling the story to the group, the CEO recounted how the company moved from lineside equipment to local factories up to 2008 – when industrial orders simply dried up – to designing and producing “karakuri” systems, which are low-energy, light mechanical systems to reduce ergonomic burden without added hydraulic or electrical systems, and then to a new digital product that measures ergonomic burden at workstations. AIO presented the product at this year’s Vegas CES show and it is attracting a lot of attention at the national level. This innovation path was not planned but occurred as a result of endless kaizen and facing the questions raised.

Indeed, the CEO explained to the students that the hardest thing he learned with lean was to face issues. Facing the issue that demand for factory equipment had simply dried up, facing the issue of solving a fundamental problem – ergonomic burden – in a green way, facing the issue of better measuring this problem in order to better solve it – and that this is the process that drove the company forward, from detailed workplace problems in sales, supply chain, engineering, and production to large changes in the company’s very offer (it is currently moving fast into services and training of its customers).

CEO’s Disciplines

The tools are absolutely the classic tools. There is wall-to-wall kanban. There is an andon light in engineering for when production needs help

There is 5S, production analysis boards, yamazumi, kaizen, and suggestions in the production area. Each department has its standards – nothing very surprising. What then, is different in the way this company uses lean tools?

If I look at it from a “culture” angle, I think I would highlight four aspects the CEO works at every day – not necessarily succeeding, but working at it:

- Problems first,

- Changes, not actions,

- Always clarifying the reasons underlying technical choices,

- Teamwork

The first discipline the CEO imposes on himself (which he explains is never easy) is to go to the gemba to listen to bad news first. The lean tools are not much more than measuring systems that reveal how the process is going. In order to get the benefit from them, you need to look and listen. For instance, during the visit with the group, the CEO pointed out the stack of kanban cards in the sales department that represented dropped orders – customers who changed their mind during the sales process and did not order. Although, like any company, the temptation is to hide this and dismiss it, here it’s made visible and the CEO asks the question: “why?” (even though most of the time, there is no good answer, but the sales team still gets to scratch its heads and think about it).

Because there are so many challenges for a small innovative company working with the biggest names of automotive and aeronautics, the CEO has set up his own lean tool to make sure he goes looking for bad news. The current key challenges of the company are represented as cards, and each day the CEO has a couple of cards saying: go and do a deep dive on this topic.

This doesn’t look like much, but it’s a radical change in management inasmuch as the CEO doesn’t manage with reports, but through genchi genbutsu in deep dives on specific key control topics to try to, well, face problems and always ask of his team: “do we understand what is going on? Is the environment changing? Are we responding fast enough, well enough?”

What Do We Change?

The next difference visitors spotted when looking at how the company works is that discussions are in terms of changes, not actions. This might sound like semantics, but the participants mostly came from large companies where the main tools of management are action plans, lists of who needs to do what. Here what they saw was that people could talk about the one change they were working on. The questions were not “what are the actions we need to implement to get this or that result?” but “what is the one change we need to test to improve the situation?”

In fact, used correctly the lean tools reveal problems, from which people ask themselves the question “okay, what do we change?” This is how the systems evolved at this company – one change at a time, tested, corrected, changed again until it sticks. When one department tries out a change it has to check the impact on the other departments, to make sure this works for the company as a whole and not just for one department. With hindsight, this is the key to making changes that stick, and evolving the company change by change.

In fact, used correctly the lean tools reveal problems, from which people ask themselves the question “okay, what do we change?” This is how the systems evolved at this company – one change at a time, tested, corrected, changed again until it sticks. When one department tries out a change it has to check the impact on the other departments, to make sure this works for the company as a whole and not just for one department. With hindsight, this is the key to making changes that stick, and evolving the company change by change.

Which brings us to his obsession with teamwork. In this case, making sure that everyone understands the impact of their work on everyone else. For instance, the visitors were struck by how many of the engineers were actually on the production floor solving problems with the team members. For instance, the company has long worked with a Net Promoter Score to keep track of how customers feel about their work, and they now have implemented an internal NPS where engineering checks how production feels about the designs they deliver to be built.

The management team meets regularly in an obeya room to discuss the issues of the company, and the problem-solving focus is on interfaces between department. The underlying question is on-going: how can we work better as a team for our customers?

One would think that this gets more natural over the years, but it turns out that whenever the company is challenged – which happens often – everyone’s reflex is still to focus on their own areas and intensify what they already do. It’s a constant effort to look up, discuss with colleagues of how the situation looks like from their own functional angle, and look for smarter ways to respond.

One would think that this gets more natural over the years, but it turns out that whenever the company is challenged – which happens often – everyone’s reflex is still to focus on their own areas and intensify what they already do. It’s a constant effort to look up, discuss with colleagues of how the situation looks like from their own functional angle, and look for smarter ways to respond.

Finally, the deeper, underlying effort common to the use of all the tools is constantly seeking to clarify, to better understand the situation, to develop models of what is going on. Every day the engineering teams meet for half an hour to have an intense, technical discussion on an on-going project, explore a technical challenge, share ideas, and clarify understanding.

How to Make a Difference

To answer your question, I believe that what makes a real difference to the company culture is leaders understanding that lean tools are not there to drive one more set of action plans, but to support each person’s deepening of their understanding of both their own job, and the purpose of this job in coordination with others to better respond to customers – which leads to step-by-step changes, as a team. The tools are just tools. In order to do the job of transforming the culture, they must recall the purpose, point to the next step, reveal problems, clarify standards, and lead to a discussion of one change at a time and visualize progress.

Tools bring culture change if you know what sort of change you’re looking for in the first place – and interpret them accordingly.