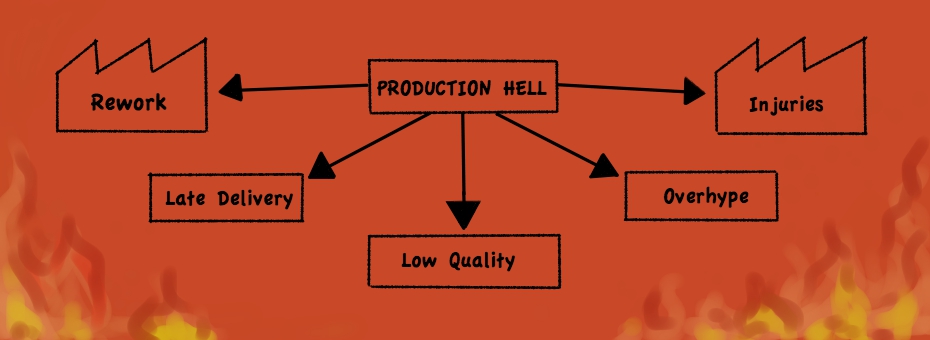

By now most everyone is familiar with the quality and delivery problems that Tesla has had with its Model 3 product launch. Even CEO Elon Musk acknowledges its subpar performance, famously referring to the “production hell” of late parts, poorly performing processes, worker injuries and reworking builds as just a normal part of its product launch process. They are not. While launches are never easy, no company that I know has these kinds of problems. Not only is Tesla months behind schedule, but it is still experiencing the kind of major build quality issues that should have been resolved months, if not years ago. Build issues recently identified by automotive engineering and benchmarking firm Munro and Associates in an Auto Week article by Jay Ramey were astonishing. Munro’s CEO remarked while reviewing a recently delivered Model 3, “look over here I can barely get my fingernail in this gap and on the other side I can just about fit my thumb. This is very unusual; the tolerance stackups on this car are just like nothing we’ve ever seen before.”

I was recently reading a Bloomberg View article by Edward Niedermeyer in which he called out the automaker for poor quality, missed deadlines and large scale re-work. “Tesla is taking automotive manufacturing back to the dark ages,” he said. Then Niedermeyer correctly identified the introduction of the Toyota Production System (TPS) as the force that dramatically transformed performance in automotive manufacturing. What’s more he even correctly stated the Toyota way emphasizes fixing the root cause of problems: “rather than trying to more efficiently repair defects, which by their nature vary wildly and thus confound standardized processes, the Toyota way emphasizes fixing the causes of the defect.”

So, I’m reading along, nodding my head and thinking, “yeah, it’s about time someone called this out.” And then bam! The End. The author falls into the same trap that Tesla apparently has: thinking that you can cure these issues in production. Just do TPS – problem solved. Not hardly.

I did not write this to criticize Tesla. I hate when people pile on a company that is struggling. I spent many years at Ford during some of its most challenging and difficult times and I know exactly how it feels. It is not helpful. In fact, I almost did not write this piece for that very reason. However, I believe that there is an important lesson here for many companies: That the time to address these issues is in development. All of the shop floor heroics going on at Tesla do little to get at the root of the problem, and they quickly burn people out. What’s even worse is that the engineers that are trapped in production hell are not available for the next program, almost guaranteeing that program will struggle thus beginning of a classic development death spiral.

Do not misunderstand me. TPS is an incredibly powerful manufacturing system. But once you are at launch, your tools, fixtures, processes, part designs, interfaces, and requirements – they are all done. The degrees of freedom remaining for the manufacturing folks are now just a small fraction of what they were during the earlier development process. Front loading your development process has long been a fundamental tenant of lean development. And the front end of the development process is where rapid learning cycles through targeted experimentation should take place. Not during the launch, let alone production. While problems may be rich learning opportunities, when it comes to launch the best problems are the ones you never have.

Development is an enterprise activity

Designing, building and delivering great products is an enterprise activity that involves engineering, quality, marketing, manufacturing as well as key suppliers. And not as some kind of “bolt-on” activity, but as full partners with real equity and responsibility. One of the characteristics that differentiates Lean Product and Process Development (LPPD) from traditional approaches is that it enables you to create new value streams, not just a product in isolation. One of the ways it does this is by engaging the enterprise early in the process in a structured and collaborative way through the obeya management system and a process that enables the principle of compatibility before completion (CbC).

In this way companies are able to identify and work through cross-functional issues early in the process while the solution space is largest. Nowhere is this more important than with manufacturing where the ability to apply manufacturing know-how upstream effectively is a powerful competitive advantagein producing both great products and manufacturing processes. Perhaps not surprisingly, Toyota excels in this capability. But so do companies like Apple who create “insanely great” products and equally phenomenal manufacturing capability.

Although it may not seem like it, I am actually rooting for Tesla. Their thinking and their products have challenged the status quo in the auto industry much as Toyota has done many times in the past. And that is good for the industry and the customer. So I hope they continue. I know they are smart and there is evidence that they are learning. In a recent tweet, Tesla’s CEO said “excessive automation was a mistake. To be precise, my mistake. Humans are underrated.” This is encouraging and sounds like a person that is open to learning. But the time for urgency, the time for bringing your sleeping bag to work is during development – not in production. So we just have to get him and his team to look up stream they may begin to understand and embrace the principles and practices of LPPD. That will finally be the beginning of the end of Tesla’s production hell.

So what about you? Are your launches a little hotter than they need to be?

(Jim Morgan will be speaking at and hosting the Designing the Future summit on June 19-20, 2018, featuring speakers from Ford, Toyota, Rivian, Menlo, MIT and more. See the full agenda: https://www.lean.org/designfuture2018 )