For those of us adjusting our routines to another school year, I’m encouraged to share a success story of lean implementation. A few years back, I started a new job (here at LEI), and had to leave the house earlier each day. With new morning time constraints to consider, after about six months of making it work, the time was right to transfer lunch-making responsibility directly to the front line.

This was not a shared vision! But with an unpredictable commute ahead, as anyone working within time constraints knows, using those precious minutes differently became a critical success factor for my day. The kids needed to take ownership without the nutritional standards dropping. This is important work! In addition to time constraints, other factors for systematizing this work included the weekly grocery bill, the amount of food waste, and morale – and by “morale” I mean the weekly refrain about not (ever, apparently) getting the “right stuff” from the grocery store.

I’d climbed through the five familiar stages:

1. Denying the problem,

2. Ignoring the problem,

3. Living with the problem,

4. Complaining about the problem, and arrived, at last, to

5. Study the problem.

In what ways was I contributing to the current condition? Up to this point, I’d tried, asked, forced and bargained to transfer responsibility and change our system – to no sustainable end. I needed to do something different. I decided to put my lean learning into action and PDCA my way into a better condition.

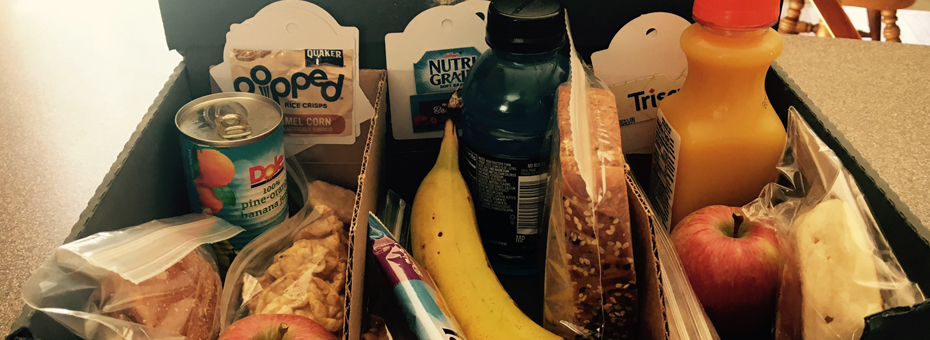

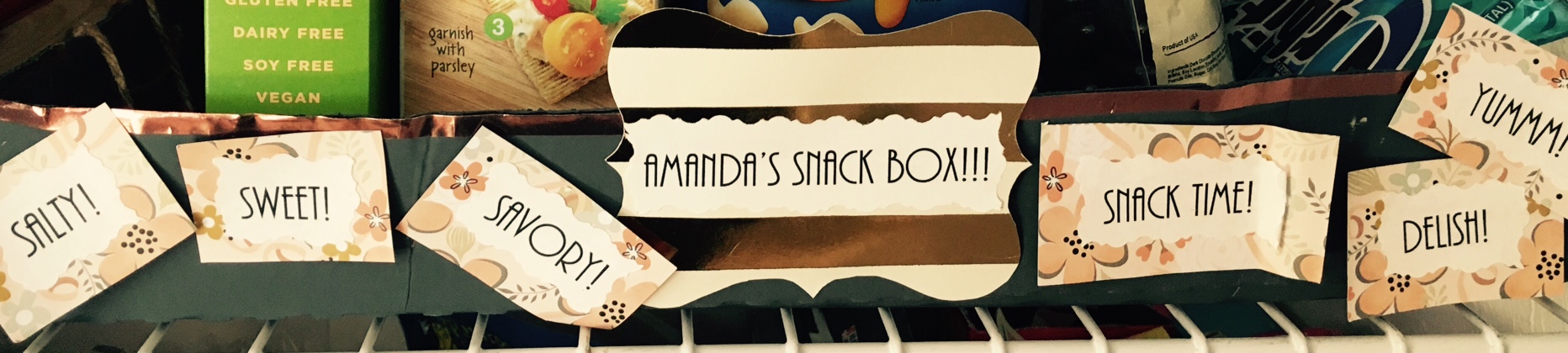

To get started, I set up a supermarket. Each kid got a box, labeled, on a shelf, divided into three rows worth of…WIP. Each row represented a day (just Monday, Tuesday, and Wednesday – my experimental cardboard box was only big enough for three days) with each day consisting of the parts needed for successful assembly: sandwich, fruit, snack, and drink.

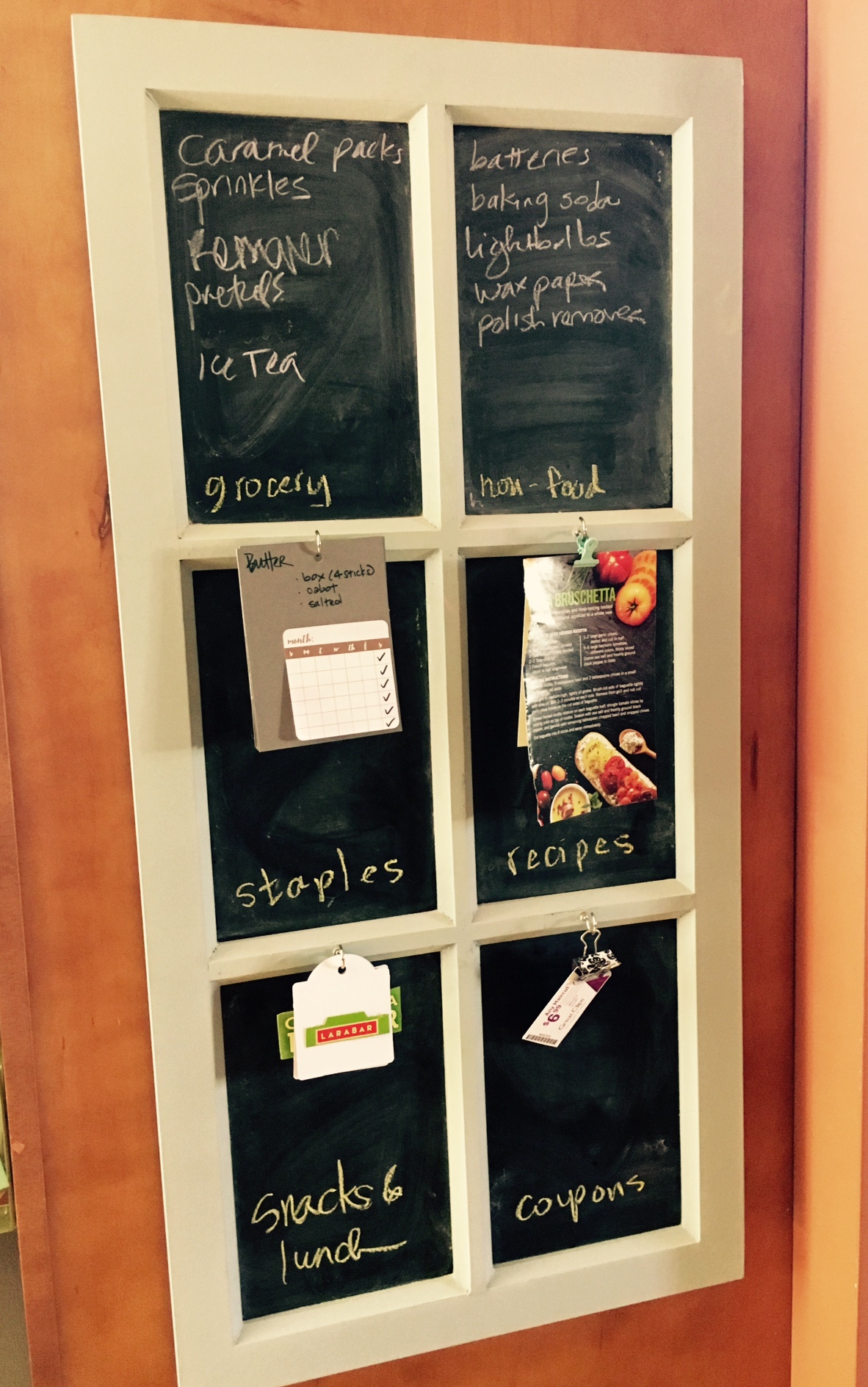

To support the supermarket we created kanban cards for each part. During replenishment on Wednesday nights, the kanban cards went to the grocery board for reorder, and the supermarket box was re-filled from the pantry. A lunchbox kanban system was born.

My kids neither wanted lunch-making responsibility, nor this “extra work.” As the novelty wore off, it was mutiny. They simply stopped engaging with it. I reflected. What is the value of this system for them? Ah-ha: getting what you want for lunch, when you want it. THAT was within my control. How could I make this system simple and fun to interact with, giving daily rewards and reinforcement for their diligence?

This next tactic might be suspect, but I started to mess with the supply. To create that value for them, I facilitated a lack of supply, as well as a method and sense of empowerment in them to change it. We collectively needed to change habits and create routines that would support the work of this kanban system.

I pulled the supermarket boxes and started smaller, with a promise: “I will buy any food you want if you write it on the board.” To build the habit of pulling for what they wanted, I stopped buying “the regular stuff” and came home, repeatedly, with only what was on the board. Cause > effect. They were not amused. And yes, they gamed the system, resulting in a couple weeks of Lucky Charms and donuts, which I obliged – such is the price of trust. I let that behavior lead us into the realm of the benefits of nutritional value (another whole set of experiments there for another post). All roads lead to continuous improvement.

But over time, with commitment, we built the behavior; we created pull.

After several months of trial and error with the grocery board: a breakthrough (aren’t those ah-ha! moments the best?). My daughter lit up when it occurred to her, standing in the bread aisle at the store: “If I ask for this bread, and put two slices in a Ziploc, and put 5 Ziplocs in my supermarket, then you’ll know how much bread you have left and when you need to buy it!” Like dominoes, the rest of the system fell into place for her. She fully embraced her newfound authority to choose, request and make her own lunches, using a system that is respectful and enables clear communication about the “right stuff” to buy and eat. She ran off to tell her brother (whose breakthrough has yet to occur).

Last night, the two kids were remaking (with paint and decorations) their own supermarket boxes while I cleared out a spot in the pantry for them and repositioned the hooks on the grocery signboard for our kanban cards. While our system isn’t technically perfect, it’s used, it’s understood, and what’s more, it’s ours.

This experiment took a long time, but it eventually clicked. In addition to shifting responsibility for the work and saving time shopping with a clear list of requests, our average weekly grocery bill has gone from around $300 to about $194. We’ve also switched to every-other-week garbage pickup because we’re no longer buying and preparing unwanted items.

In reflection, what most surprised me is how complicit I was in contributing to my own burden. By taking it all on – making the lunches and intuiting all the possible groceries anyone might want each week – I was sacrificing valuable time and energy. If motherhood is a balance between taking care of my kids and teaching them to take care of themselves, the work is in the balance.

The learning to be done was equal parts them taking responsibility and me learning how to share it. It wasn’t until I understood the value in the eyes of my “customers” that I could share the burden, empowering them through new routines and behaviors with the authority to manifest their own destiny. And that really is their work to do, because by taking on the work myself, I was taking away their opportunity to directly experience their own competence and power.

In this case, a kanban system helped us to achieve interdependency, level-load our work, and reduce waste. Recommended reading that helped me learn to practice these methods includes Lean Production Simplified by Pascal Dennis and Kaizen Express by John Shook.

Turning basic knowledge into applied practice created a deeper level of understanding and skill. I recommend practicing your lean learning wherever you can, and good luck with your experiments!