Having knowledge of and understanding gemba walks is hugely important, but there is another crucial factor that can make a vast difference to what you see and don’t see, your behavior as a management team and the decisions that you make.

Approaching gemba walks with the right mindset can be the deciding factor in how effective the management team is in eliminating firefighting, making good decisions, developing people and improving performance.

For example, I recently joined members of a senior team during one of their weekly gemba walks. The organization is regarded as a mature example of continuous improvement and lean, but with a closer look there is evidence that it is being impacted by gaps in mindset, leadership behavior and management routines.

“At the start of this management routine, the team stood around the visual management board waiting for the operations director. About five minutes past the hour he turns up with a face like thunder and greets the team with a mumbled “good morning” and a nod.

The quality manager then picks up the leader standard work form for the meeting and we’re off. Initially the quality manager leads the walk, but within minutes the team starts splintering into sub-teams. A few members of each team seem to be pointing issues out while the other members look on in silence. I stay close to the senior members as they follow the operations director, who is now leading them through the facility. We move from process to process, zigzagging around, looking to see if people are busy, discussing individual employees, providing instructions and discussing possible changes.

About 15 minutes from the end of the meeting, the operations director informs the production manager and the logistics manager that he’ll see them at 1pm for the planning meeting and leaves the group. Within minutes the rest of the team disperses and the quality manager adds his final notes to the paperwork and heads back to the visual board to posts it back in its placeholder.

I discuss the meeting with the improvement manager. He tells me that this was a good meeting and that often several members of the team get a good dressing-down if standards have fallen or problems are found. Also, he added, the managing director and other members of the executive team do not like to join the meeting as they want to stay strategic and not cause concern amongst the staff by walking around as a group. Looking at the notes from the gemba walk, the team had noted housekeeping issues, floors that needed repainting and additional signage that was needed. Never mind the fact that we’d walked past numerous processes that were missing their targets and staff that were waiting for work while others had work waiting!”

If the purpose of the gemba walk were to just get through an hour of the work day and show your people where they are wrong and what they need to do and think about – then well done, but you will have just wasted an hour of their lives.

The problem is that leaders often approach both Lean and visiting the workplace on gemba walks with a fixed or closed mindset, instead of an open and discovery mindset. The former focuses on blame, solutions and showing who’s boss. The latter focuses on learning, cutting through the noise and developing a greater understanding of the real issues that are impacting people, process and business performance.

Too often we see leaders puff out their chests as they walk around with their management team, almost as if they are taking a bunch of naughty kids out for a walk. The leader makes a point of showing everyone who’s boss and pointing out issues that they are not happy about or need to be addressed. In other words, they are hard on the people and soft on the process. Instead of going to see, observe, and discover problems and issues that stop their employees being successful, they go to gemba to be seen and show others what they know and want done.

Indeed, Fujio Cho, former chairman of Toyota, summed this up when he said that there were three key behaviors to lean leadership and to “go see, ask why and show respect.”

But why is it that leaders, like so many others, find it so difficult to adopt these three key behaviors? And what can we do to change our mindset and start approaching leadership and gemba walks in the right way?

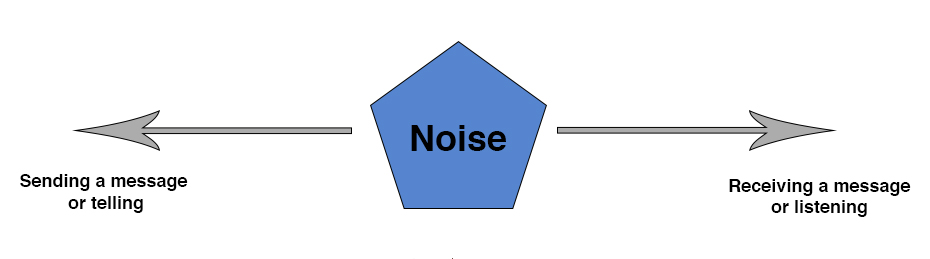

Firstly, I believe it is helpful to understand the two sides of the communication process, i.e. (1) Sending a message, or telling and (2) receiving the message, or listening. Often there is too much emphasis on the left-hand side and sending the message. Interestingly, Dr. John R Schermerhorn, 2011 found that there are typically six sources of noise within interpersonal exchanges that impact its effectiveness, they are physical distractions, semantic problems, mixed messages, cultural differences, absence of feedback and the effect of status.

From a leadership and gemba walk perspective, key factors that create noise and block the right mindset and behaviors from being adopted, are:

- Distractions

- Not having a clear understanding of the purpose

- Mixing different types of gemba walks or going off-track by not sticking to the plan i.e., going off track, splintering into subteams

- The maturity of the environment is low and does not support the team in seeing flow, understanding when it breaks down and learn about performance problems

- Not able to see and think at the right level and getting drawn into the weeds

- Status

- Going with a solution in mind and showing that you are the Boss, a senior leader or super clever and know what needs to be done.

- Absence of feedback

- Being task-oriented and mistakenly seeing gemba walks as a management task that needs completing instead of a management routine consisting of PDCA (with feedback loops before, during and after the walk)

- How we think about problems, standards and management’s role in improving the business

- Assuming that we know what the problem is, where it is and what is causing it before confirming it

- Behaving inappropriately and believing that they are there to convey problems, punishment and actions

- Do we believe problems are bad and standards are there just as a guideline?

- As leaders, managers and supervisors do we believe that improvement is the role for others.

To move forward, it is a relatively simple set of rules and state of mind that we need to adopt for a short period of time (like being polite at a dinner party, when you really want to watch the game). We need to adopt an open and discovery mindset where we look to learn. Establish some rules as a simple mechanism to help you discover, learn and make better decisions.

- Develop a clear purpose. To run effective gemba walks the team needs to develop a clear understanding of their purpose. The purpose should be one that seeks to learn, discover, develop a greater understanding of the work, and gain consensus amongst the management team about the issues impacting performance and obstruct staff winning and being successful.

My definition of the purpose of a gemba walk is that it is a:

Management practice to learn more about the organization and help grasp the situation, by developing a collective understanding and agreement of leadership at different levels to develop their leadership skills and improve business performance. It’s about learning and discovery; not the fixed mindset of conveying solutions and blame.

- Establish a management routine. Your goal should be to complete the walk with a management routine consisting of PDCA to help with your continuous learning, improvement and development. PDCA should be applied multiple times at the beginning, during and at the end of your routine. At the end of the routine you’ll want to find out what others have seen and believe the problems are, before trying to understand what is causing them.

- Establish behavior standards. As a leadership, team start adopting behavior standards and to ban the “Gotcha” questions, no telling, showing, pointing out, solutions or blame. If leaders are still acting with traditional management thinking then they are in the wrong meeting, remember Go See, Ask Why and Show Respect.

- Eliminate noise. First develop a greater understanding of the noise that disrupts you and your leadership team from observing. Then establish sacred time and get members of you team to stop/correct you when you claim to know what’s best, go offtrack into other processes or discussions, get into solution-and-blame mode, provide instructions and/or point out what “needs to be done.”

- Develop capability. Develop the capability of your team to grasp the situation by discussing what reoccurring issues are impacting your value streams. You want to know what’s keeping you from delivering what the customers want and keeping your employees from winning and being successful. Within the feedback session, build consensus about the key reoccurring issues and don’t assume you know what is causing it without confirming it over a period of time.

What do you think? Are fixed mindsets and noise impacting the behavior, decision-making and performance of your organization?