I have applied value stream mapping in the manufacturing environment and on a few administrative processes, but I am struggling with applying it in product development. Every time I get started with the current state map, everyone says “it depends” as they say each project is different and there are so many data flows occurring at the same time that it is difficult to keep track. Do you have any tips?

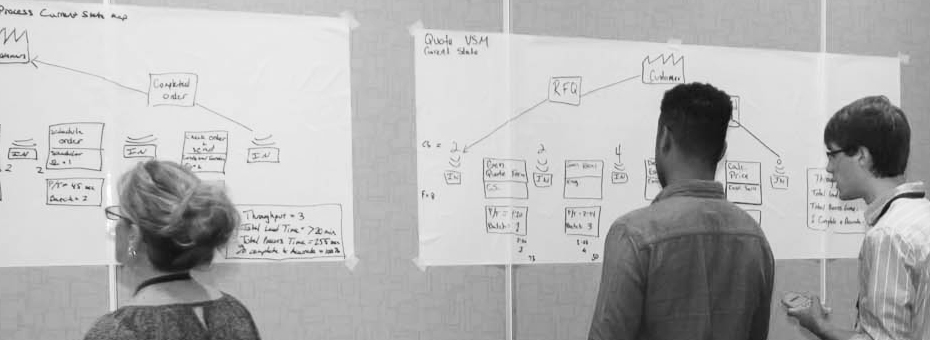

I do. Value stream mapping is a proven approach for understanding any process, seeing the wastes within it and helping you to formulate a vision of where you want to take your process in the future. It is potentially even more valuable in Product Development than than in manufacturing since “seeing” waste in the virtual and somewhat complex world of product development and pinpointing its source is challenging. But you’re right, some people do get caught up in the complexity of the process and lose sight of the goal of VSM – which is to find and eliminate waste. So here are some adaptations to the VSM to help you get started and keep your product development teams more focused:

- Pick a specific product to map: Many people fall into the trap of mapping the “generic” PD process for their product. This leads to a lot of “it depends” and anecdotal comments about pain points. It is better to pick a specific product/project that you have recently completed. This calibrates everyone to be talking about the same value stream and will be able to provide you more consistent data. Yes, all projects are different, but the wastes are systemic so frankly it does not matter which product/project you choose to map. The wastes are waiting to be found!

- Decide on the level of process you want to map: Unlike manufacturing which has one level of processes, PD has multiple layers of processes:

- PD value stream –e.g. the end-to-end high-level “stage gate” process

- Multi-functional – e.g. component design; engineering release; DV, PV, etc.

- Single-function – e.g. durability test, finite element analysis, etc.

- Process level – e.g. writing a test report

Each level will clearly surface opportunities for improvement. My advice is start with the higher level to understand the overall flow first and then dive deeper where needed to pinpoint the waste. This should help you to avoid getting lost in the details.

Each level will clearly surface opportunities for improvement. My advice is start with the higher level to understand the overall flow first and then dive deeper where needed to pinpoint the waste. This should help you to avoid getting lost in the details.

- Engage the right people to do the mapping: Like product development, VSM is a team sport. Given the virtual nature of PD today you will not see all the waste by simply walking around the office. The people who are part of the process need be involved so they can surface the wastes/challenges they are facing. Otherwise, those wastes will remain hidden.

- Walk the flow: Even though most work in PD goes on virtually over a long period of time, it is still important to go to the gemba to see the work environment and speak with people at their desks to get their unvarnished view of the current state.

- Capturing times: In the factory we use stopwatches to measure time – in product development we use calendars. Given the long duration of times of tasks, it is impractical to capture real-time data like we do in the factory. It is best to use times based on the given product/project you have decided to map (see above) so at least you have a relatively consistent set of times. We don’t need data rounded to four decimal places; rather, we need data that is directionally correct to understand the current state. Don’t forget to distinguish between the time elapsed on the project (i.e. the time it is in the system) and the actual task time (time spent working on a particular task).

- Positioning activities: As you follow the flow in PD you will quickly discover that not all activities are sequential as they are in manufacturing. In fact, many groups may be working, collaborating and integrating in parallel (or should be!). Be sure to not only capture what is happening and how long it took but also when it occurs. This may help you identify areas where you have unsynchronized concurrent waste and arrival variation and help identify opportunities to better front-load.

- Spend time on the linkages: Many of the wastes you find in product development actually happen at the interfaces. Take the time at each step to understand what your downstream customer really needs and when they need it. Understand what inputs are necessary to each step in order to do the task. This will help you to better understand quality/maturity of the information flowing through the overall process.

- Don’t forget the rework loops: Rework can at times be difficult to see when mapping product development processes. Some iterations may be discovery of knowledge while others are pure waste. Challenge the team to distinguish between the two. Finally, look carefully into each process box to see if rework is hidden within. Sometimes we label tasks with “refine,” “review,” or “reevaluate” – which on the surface may appear to be adding value, but in fact are code-words for “rework.” If the word starts with “re-” it is more often than not rework in disguise.

I hope this advice puts you in a better position to identify waste in your PD value streams. Keep it simple, ask questions when you have a doubt, and engage the people who do the work to do the mapping and the opportunities will come flowing out.