LPPD is about continuously innovating to find a new and better way to deliver new value. It’s about creating the future. But I recently had an experience that reminded me that not everything should change

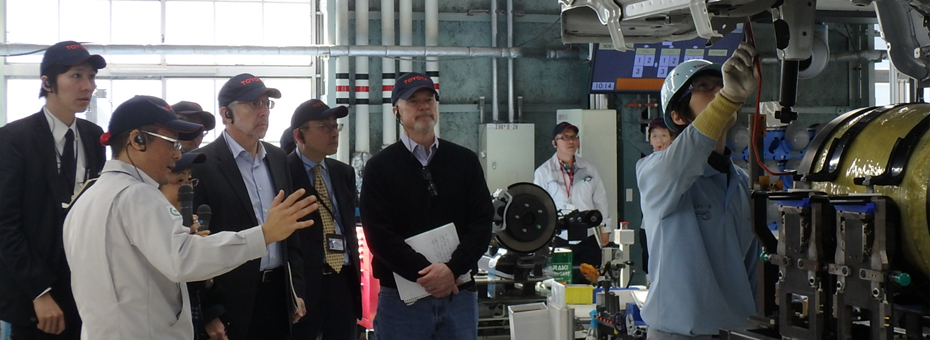

Last month I traveled to Toyota headquarters in Japan with Jeff Liker for a research project. We wanted to learn more about the engineering and collaboration that created the Toyota New Global Architecture (TNGA), the strategy and innovation behind hydrogen vehicles, and how they had adapted and improved their development system to meet the increasing demands of the ultra-competitive global auto industry.

It had been over a decade since I’d last been at Toyota, and even longer since I’d first learned about the principles and practices that made up the powerful system of lean product and process development (LPPD). So much had happened to both Toyota and the rest of the world since then. And so as our plane crossed the Pacific, I wondered to myself, “How much have Toyota and its development practices changed since I first began my LPPD journey?”

Jeff and I were definitely not disappointed with our visit. From the shop floor to the test track Toyota shared with us its game-changing new products, powerful new methods and breakthrough technologies. But what impressed me most was what had not changed.

LPPD as practiced by Toyota is still an enterprise-wide system that creates new value streams. It is not just a scheme for one-off products or a discipline solely for product engineers. So when Akio Toyoda, President and CEO of Toyota committed the company to creating “ever-better products” he was not just talking to product engineering. He was providing a “true north” for the entire enterprise. Directing everyone at Toyota to provide ever-greater value to the customer through their work on new products and processes. This meant improving both product attribute performance and improving the quality or efficiency of all product delivery mechanisms – especially manufacturing processes.

I’d like to share just a couple of examples of how Toyota continues to simultaneously develop products and processes focused on creating ever greater value for the customer.

The first example is how Toyota went about dramatically improving vehicle ride and handling characteristics. One way to improve a car’s ride and handling is to increase body stiffness. Consequently Toyota set an objective of increasing stiffness from between 30 percent to 60 percent depending on the particular car. One way to reach this goal is increasing the number of spot welds on the body. However, this can significantly increase cycle times and/or drive costly investment in the assembly process. In many companies this conflict would result in cross-functional battles, compromised product and process performance, and far less value delivered to the customer. But Toyota PD and PE engineers worked together to improve product geometry and develop Laser Screw Welding (LSW) technology that requires less than half the cycle time of conventional spot welding and less plant-floor space, yet still delivers the required body stiffness. Nothing less would have been acceptable. LSW also has the added benefit of being far more flexible than traditional spot welding for launching additional new products and can weld multiple material types.

Another product priority for Toyota is to reduce weight to increase fuel efficiency. One way to accomplish this is to engineer parts out of high-strength, lightweight materials that can replace multiple part sub-assemblies and be thinner gauge – thus reducing vehicle weight. However, some of these materials have to be superheated prior to forming. Traditionally, this has required very large, dedicated gas ovens that heat steel blanks in large batches, plus an added operation to remove the layer of oxidation caused by the heating process. While this might be an acceptable compromise for many companies, working in batches and adding operations in TPS is a non-starter. Once again, Toyota PD and PE engineers collaborated to tailor blanks and create a joule heating process that heats blanks one at a time, in 5 to 10 seconds – and with no added operations required. While some companies are satisfied with improving their products with added costs passed on to their customer, the LPPD system embedded at Toyota enables them to deliver lighter, safer vehicles AND at even lower costs than their predecessors.

These simple examples illustrate Toyota and LPPD at its most fundamental. Leveraging collaboration, learning and innovation in product and process development to deliver solutions that maximize value to the customer.

So what did I learn on my journey? That in the midst of continuous improvement, Toyota is still grounded in the strong fundamentals that make up LPPD and focused on delivering “no compromise” value to their customer. And by continuing their drive to deliver ever-greater customer value through both product and process innovation, Toyota can achieve improvements far beyond those possible by “product only” solutions.

So, is your organization collaborating to develop both product and process solutions in creating new value for your customer, or settling for compromise?

For me LPPD embraces both a driving passion to make great products and an absolute reverence for the ability to make them well. This is still the most fundamental, and perhaps most powerful way of creating new value.