Learning from a Bad Process

Let me describe a key lean product (and process) development principle by way of a story. Let’s look at an example of a process that really needs to be improved: the hand washing process in airport restrooms.

Since I travel frequently, I unfortunately get to spend a fair amount of time in and out of public restrooms, especially in airports. Most that I visit have water on the counters, water spotted mirrors, errant liquids on the floor (not a comforting sight), and paper towels strewn about. It is easy to think “society is full of slobs.” But this line of thinking is reminiscent of one of Jim Womack’s e-letters, “Bad People or Bad Process?”

We can all agree handwashing is an important step in the overall restroom process. But what does this have to do with process design or for that matter, lean product and process development? Here’s a process where it’s all about letting the basic work to be done define the process design.

Since restrooms and hand washing are not new concepts, you would think that the design would be more conducive to cleanliness. Most airport restrooms are designed based on past experience/designs, not based on thinking deeply about the actual work to be done. Sound familiar?

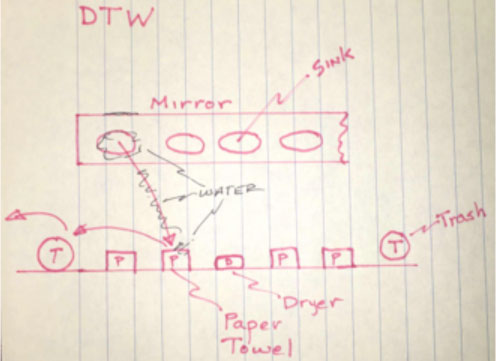

The thinking might go something like, “We need a sink to wash hands, a soap dispenser at each sink, a paper towel dispenser, and a place to throw the trash. And since all restrooms have sinks behind the mirrors, we will need big mirrors, too.” This yields layouts such as this from Detroit Metropolitan airport (see right).

All force the “operator” to wander the restroom with wet hands dripping. Conscientious patrons may shake their hands off in the sink, only to spatter the mirror. The resulting process is arguably NOT so clean, which is ironic since really that is it’s only purpose. So if we think about the real work to be done, we want to keep the water in the sink, not on the counter or floor. By doing this we keep the hand washing area cleaner and make it easier to maintain as clean for both workers and patrons/users.

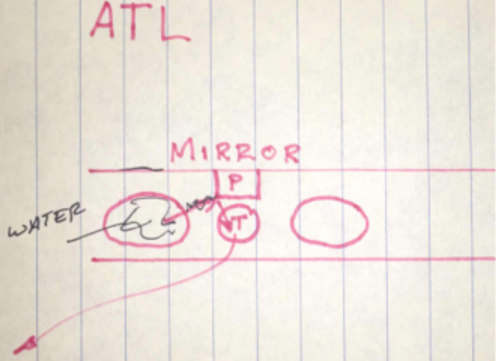

Interestingly enough, someone in Atlanta did think about this… a little bit at least.

This layout at right minimizes the reaches, but still results in a thoroughly wet countertop between the sink and the dispenser as well as a wet mirror.

What’s the lesson to be learned here?

Before jumping to a process design based on past precedence, think about the elemental work and the issues experienced by the user.

I honestly believe that the reason we do not hear more about lean PROCESS design is that it is tedious, detail-oriented work. By the time a new product is so close to production, we have simply lost the time and energy to think this deeply about the real value-adding production work to be done.

Learning from a Better Alternative

About 20 minutes from my house in the small town of Metamora, Michigan is a restaurant called The White Horse Inn. They have taken the hand washing process to a whole other level. They’ve solved some problems.

Their sinks are essentially a large metal trough with multiple faucets installed along the length. The faucets themselves are Dyson Air Blade taps – faucets with dryers built-in. So the water is essentially blasted back into the sink. Pretty cool.

But before you think this is the ultimate solution, let me tell you there is still room for improvement (as I screwed it up). The faucets are so new, I had never seen anything like them. So I dispensed foaming hand soap onto my hands and proceeded to place my hands under the dryer fins, promptly blowing the foam out of my hands, all over the mirror in front of me, and onto a sign that explained how to use the faucets.

Think about this for a minute.

If a sign was needed, I couldn’t have been the first person to do this! This design had created a new kind of mess. So even Dyson has an opportunity to improve their product based on the work to be done (dryer will not activate unless the faucet has been activated first?).

What’s more, if we time-studied the act of washing and drying, we might find that a bottleneck has been created by combining these two actions into a single position.

Finally, the White Horse could do even better, and like Disney, remove the mirrors from behind the sinks and place them on the way out the door to keep the crowds from lingering by the sinks and minimize the need for cleaning. After all, what do mirrors have to do with hand washing anyway?

But you get my point. We’re all short on time, but think for a moment with your team about the real work to be done in any process you’re working on or design you’re creating. Are you building from past experience or actual customer needs? Are you building from past experience or building to solve problems? It’s a worthy question, just not an easy one.