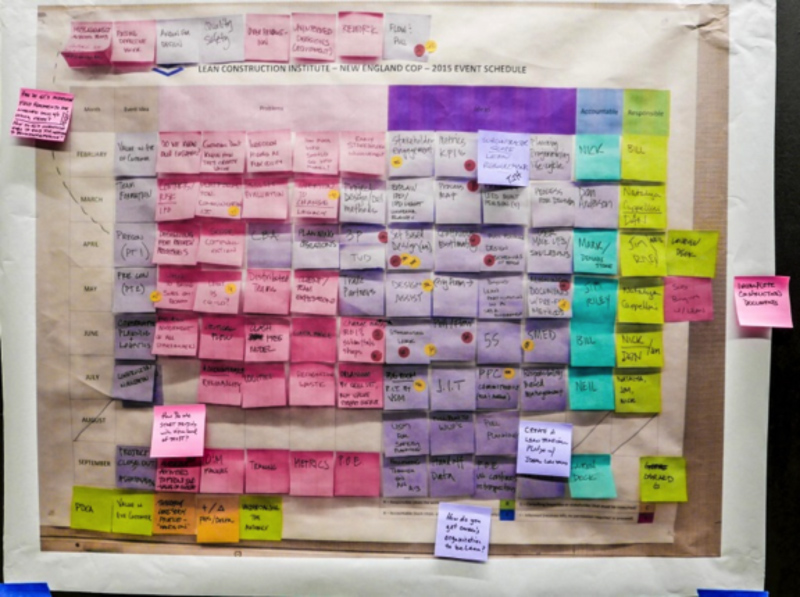

Image courtesy of LCI New England

Construction is a dysfunctional industry fraught with conditions of poor quality, cost overruns, and late projects. We’re similar to manufacturing, too. Our work is about moving from concept to early design to engineering to production. And we even use the same lingo – value engineering, change orders, and commercialization. We’re poised and ready for radical transformation, much like the manufacturing industry was when many in the industry adopted Lean.

It would seem, then, we should be able to accelerate Lean adoption and make the kinds of big leaps that manufacturing has enjoyed, right? Sadly this is not the case, and I’m sure not a surprise. Many in our industry have to a great degree fallen into the same trap as others: over-reliance on the much vaunted “tools of waste elimination” as opposed to a broader, principle-based approach. This approach is not based on a beginning-to-end, system-view, so results are rarely enduring, have unintended consequences, and may remove a value-added feature.

It would seem, then, we should be able to accelerate Lean adoption and make the kinds of big leaps that manufacturing has enjoyed, right? Sadly this is not the case, and I’m sure not a surprise. Many in our industry have to a great degree fallen into the same trap as others: over-reliance on the much vaunted “tools of waste elimination” as opposed to a broader, principle-based approach. This approach is not based on a beginning-to-end, system-view, so results are rarely enduring, have unintended consequences, and may remove a value-added feature.

What to do?

Start at the beginning! Understand who our customers are and what they value. And use this as our True North. That’s exactly what the Lean Construction Institute’s New England Community of Practice recently did by inviting John Shook to one of our monthly events. John helped an audience of 65 see that “everyone in an organization has a problem to solve on behalf of creating value for the ultimate customer.” (This concept is largely lost in our industry because we are likely to be disconnected from the ultimate customer, focused on our own “means and methods.” We focus on what and how, not on why – which stifles creativity, creates animosity and hides waste.)

Some nuggets from John on how the construction industry might use Lean principles to focus on our customers and start a true transformation:

- Our industry should strive to engage in “daily practical problem solving” where we “elevate and solve problems one by one”

- Kanban is an example of making order of non-value work with value-add work

- “As long as we are hiding problems, we will have a sick organization”

John’s comments resonated with a group of “owner” panelists that followed his remarks. The panelists we invited are owners of some of the region’s largest and most distinguished public and private organizations – and for us, they represented the customers of the construction industry. These customers told us that the process of design and construction is opaque, and blame is easy to shift. They noted that we have sharply honed our adversarial skills due to our piecemeal approach and many years of fragmentation. But – they do see lean as an overarching and potentially effective countermeasure.

Some nuggets from our customer panelists:

- “Don’t be afraid; let’s grow together” (a message from a large public enterprise to the project team that it’s better to experiment and fail than to continue our existing wasteful ways)

- “Delays to tenant occupancy change our yield. I’m willing to pull the construction stakeholders into the tenant lease so they understand value” (from a national leader in developing hi-tech lab space)

- “The slowest part of what we do is decision making. Integrated teams expose the cost of bad and slow decisions” (project director at an Ivy League school

Interactions such as these, where we share learning and barriers to creating Customer value, have generated a call to action within our LCI Community of Practice.

We are now centering our year-long learning, one month at a time, around 5 principles of Lean:

- value in the eye of the customer

- working in value streams

- maximizing flow and pull

- empowering the people in the team

- pursuing perfection

Our evening with John Shook and our other panelists was a success largely because we gained a sense of humility about where we are in our lean journey. The sense of optimism and potential in the room far outweighed any dismay about the newness of our journey.

We’re excited to see where this work takes us and would love to hear your thoughts and questions about the opportunity for lean thinking in the construction industry. Tell us below!