A commonly used definition of Lean is the total elimination of waste (time, resources, energy, etc). But what is the purpose of this? Does the purpose matter? If we look at the origins of this principle in Taiichi Ohno’s the Toyota Production System, the goal for Toyota in 1978 was indeed cost reduction:

“Cost reduction must be the goal of consumer products manufactures trying to survive in today’s marketplace… A total management system is needed that develops human ability to its fullest capacity to best enhance creativity and fruitfulness, to utilize facilities and machines well, and to eliminate all waste. The Toyota production system, with its two pillars advocating the absolute elimination of waste, was born in Japan out of necessity.”

But it was also about much more than this. Eliminating waste makes it easier to see and find problems, which is the first step to solving them. It removes frustrations, which improves worker and customer satisfaction.

The purpose or goal of Lean efforts could be cost reduction, shortened lead time, improve customer satisfaction, removing frustrations, improve quality, etc. The specific goal doesn’t matter, but having consensus for the goal does, which enables improvement efforts to be aligned towards meeting the goal. The goal mattering to the people doing the work is important to get consensus towards the goal. For example, in the clinics we work with in Lean for Clinical Redesign there is consensus that our purpose is to improve patient care.

Ohno says, “When thinking about the absolute elimination of waste, keep the following two points in mind:

- Improving efficiency makes sense only when it is tied to cost reduction. To achieve this, we have to start producing only the things we need using minimum manpower.

- Look at the efficiency of each operator and of each line. Then look at the operators as a group, and then at the efficiency of the entire plant (all the lines). Efficiency must be improved at each step and, at the same time, for the plant as a whole. “

Ohno goes deeper on the second point:

“Understanding is my favorite word. I believe it has a specific meaning – to approach an objective positively and comprehend its nature. Careful inspection of any production area reveals waste and room for improvement. No one can understand manufacturing by just walking through the work area and looking at it. We have to see each area’s role and function in the overall picture.”

We frequently miss these points when we talk about waste elimination. Putting them in a different context from cost reduction, they might read:

- Eliminating waste only makes sense when it is in service of your purpose.

- Understand how the system fits together and how each role supports the overall picture and analyze it for waste at all levels in service of your purpose.

What problems do we run into when these points are not kept in mind? Do we spend time, resources, and energy on efforts that don’t support our goals or purpose? Do we eliminate waste from our individual perspective that is necessary or valuable for the system? How can we understand how the whole system fits together?

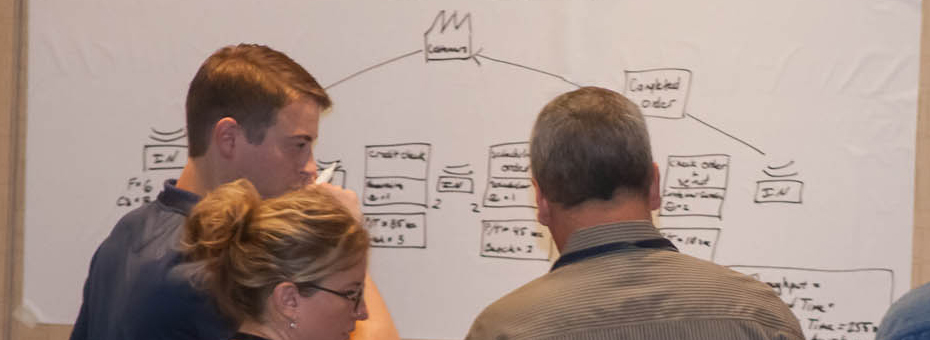

Value Stream Mapping can be highly effective for understanding the whole system and how each role supports the overall picture. The conversations that happen through the process can be invaluable for understanding how the system fits together and how each role supports the overall picture. It can become obvious that redundant work is occurring by multiple people. How activities that an individual may perceive as waste support the overall picture can become clear.

The clinics we work with usually map a patient experience from the time they check in until the time they check out using time and percent complete and accurate as metrics. The waste the clinic staff identifies helps the staff see where they need to improve and what experiments they may want to run. One of the things we have learned with Bronson Healthcare Group is that the real benefits of the experiments aren’t going to show up with time metrics. The goal isn’t less time spent with patients; it’s about having the appropriate time with patients in order to provide the appropriate care. Sometimes this means shorter appointments, and sometimes it is longer appointments depending on the patient and their needs. What matters is the right care, at the right time, at the right place. In this case, this is the purpose the teams aligned around and worked to eliminate waste in service of.

Seeing waste from this viewpoint—how it stands in the way of achieving our goals—enables us to focus our energy on what we should be working on. A hunt for waste that is not aligned with a purpose supports nothing.

Lean for Clinical Redesign is a Professional Collaborative Quality Initiative (CQI) that supports the development of sustainable lean learning programs within Physician Organizations (POs) and Practice Units (PUs) in the State of Michigan. Lean for Clinical Redesign is part of the Michigan Quality System at the University of Michigan Health System. Funding for Lean for Clinical Redesign CQI is provided by Blue Cross Blue Shield of Michigan (BCBSM) and Blue Care Network (BCN). BCBSM’s Value Partnerships program provides clinical and executive support for all CQI programs.