As part of our local manufacturing association, we tour about 20 facilities per year to see best practices and lean initiatives in action. In almost all cases these best practices take place on the operating side of the business with a common lament, “We can’t seem to get the rest of the company to fully buy in!”

At ProMed we suffered the same ailment, with little change after 5 years of effort. As a result, we ended up having two very distinct cultures: one that was growing and improving and excited to see change happening and another that clung to past practices. Two of ProMed’s leaders attended a seminar called “Lean Applied to Sales” to try to gain some insight on getting the attention of folks outside of operations. The seminar was great; most interesting was that 90% of the attendees were from the operational sides of their organizations. These were folks like ProMed, trying to figure out how to break this log jam.

In a contract manufacturing organization like ProMed it’s especially critical for the entire organization to understand new technologies, lean processing platforms, and the improved capability of the workforce. This deep understanding of “what’s new” should drive the manner in which we as an organization present ourselves to the outside world, including the way we deliver quotes and convey our “differentiating values”—always with the goal of producing wins when facing the competitive landscape.

After attending the Lean Applied to Sales seminar, we knew that we needed to re-think the way we all shared what was new, what was better, and where we were headed. We came up with four concepts that we implemented to help us achieve the company objective of unifying our personnel towards the same directives. This included establishing ProMed University, the Boardwalk, the Continuous Improvement Game, and One-Pagers to raise the skillset, involvement, and unified vision of everyone in our organization.

ProMed University

We’ve had several members of our management team get out and learn about our industry and lean culture, but we needed a centralized location for all the knowledge we were collecting. So we developed “ProMed University”, where we store books, presentations, and training classes. All of this information is available to every employee. We’ve seen many people check out books, attend training classes, and even ask questions like, “When is the next training class?” and “Do we have this book in the library”? In some cases we invite customers to attend our internal classes, such as Introduction to the DMAIC Process and Introduction to Statistics, which has helped grow relationships and further our mutual respect. For us, this is a great example of a real life cultural change that sprung out of a basic education tool.

Boardwalk

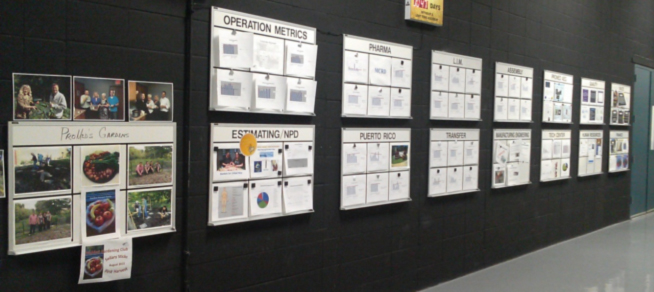

In lean thinking and practice, we all talk about the importance of “going to the gemba.” Usually this entails going to a specific work area and addressing concerns of that team on a daily basis. As senior leaders, we still visit different work areas daily, but now we’ve moved all team performance boards to a centralized area we call the Boardwalk (Figure 1). Our team boards are on a wall on the way to the cafeteria and accessible to everyone. People get to see all the boards and the data displayed that in the past they normally wouldn’t have access to. The boards that get the most attention are from New Products, Advanced Engineering, Sales, and Finance. This boardwalk is a key “stop and discuss” point on all customer tours. Here we are able to show a summary of our company’s performance over the past year as well as our active projects. This has been a great sales tool, but the real benefit, which we could never have predicted, was the positive impact of this on ProMed’s employees.

Communication is a universal area of concern for many organizations. What better way to open the door to communication than to publicly display company performance. This transparency provides employees with new confidence in the company’s direction. It makes people feel like they’re a part of something. Since the implementation of the Boardwalk our employee satisfaction surveys show a much higher approval rating on organizational communication. These are huge wins for us, and we’ve all become better speakers and listeners.

|

|

Figure 1: Boardwalk |

The CI Game

|

|

Figure 2: Sorry ® Board |

There is nothing like a little healthy competition to encourage folks to participate in an activity? If you remember, our first (golf themed) CI game resulted in 85% participation and 839 implemented suggestions for organizational or value stream improvement. The game concept was an attempt to get everyone involved in ProMed’s Lean Journey. We put all of the folks that more or less had previously been “sitting on the sidelines” on the same team, which encouraged their active participation. Surprisingly, this team ended up being a strong contender every month for the top spot, which showed us that putting the “disengaged” employees together forced them to raise their game, or just make their work visible and known to others.

If you read our previous article, “Tee Up Your Continuous Improvement,” you are already familiar with the game concept, but for those who are new to the idea here is a brief explanation. Team members work together to come up with improvement ideas for their area or other areas in the company and drive the idea to fruition. After its completion the team gets credit for the completed CI and the teams with the most completed CI’s are given an award and small prize. For our next/latest game, modeled after the game Sorry® (Figure 2), we created cross-functional teams, allowing relationships to begin with people who previously never worked together. In some cases they didn’t even know each other’s names. We started this game in August 2013 and in five short months we saw 622 suggestions for improvement across the organization.

One-Pagers

We discovered that an effective way to get everyone on the same page was to write a series of 1 page articles about key things going on at ProMed, especially about our Lean journey and success. This was an extremely valuable exercise, and it allowed ProMed to have a consistent message when communicating outside the organization. These articles focus on the key things a customer may want to know about our organization or a new capability that we are selling. We use them in email blasts and as handouts at trade shows. Creating these 1-pagers has brought a sense of pride to the team members who have written them. Operations people love seeing their thoughts and activities become an integral part of communications materials dedicated to educating the entire organization as well as the sales and marketing process. Titles of some of these articles are: “Lean Six Sigma”, “Customer Focus”, “Designing for success”, “Focusing on Reducing Your Cost”, “New Product Development Process” and “ProMed’s Quick Turn Option”.

All of our customer tours include visual confirmation of the activities described above. We wear “lean on our sleeves” at all times and consider it a cornerstone of our culture. Slowly we have been getting the entire organization on the same page and are making great inroads with our customers with these activities. Most of all, we’ve made the lean journey fun by finding ways to get everybody on board and invite meaningful participation.

Tina Roach is Lean Six Sigma Manager of ProMed Molded Products and can be reached via LinkedIn

Pete Mangan is president of ProMed Molded Products and can be reached via LinkedIn