Dear Gemba Coach,

I am working as a lean expert in a European multi-national with more than 25 manufacturing sites worldwide. We have started a continuous improvement process with dedicated lean experts at each site. Until now our focus was on lean training. We link projects to a site impact-priority matrix. Management wants the improvements projects to be linked to key performance indicators (KPIs) such as on-time delivery and cost of quality. And they want these KPIs identified, and that we report our progress on how the projects are impacting these KPIs on a monthly basis. Could you guide me on how this can be done?

Tough question, but it can be done. I know a CEO who is an experienced hand at lean turnaround and had worked with a sensei for many years before—but his experience should give you hope.

So how do we do it? First, let’s take a step back and think about lean programs in large, geographically dispersed companies. Let’s be clear about recognizing that broader goals at every level will have components of explicit business results, as well as organizational capabilities.

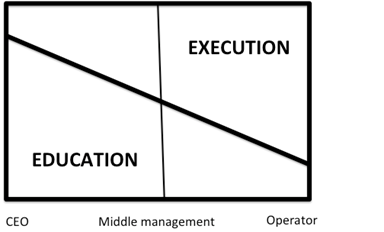

I believe that the core lesson of Toyota is to shift from JOB = WORK to JOB = WORK + KAIZEN. In other words, everyone, from the CEO to the operator, must factor in the education aspect (learning) of any job as well as the execution part (getting the job done. People at different levels will have a different mix of emphasis. At the CEO level, the lean job is mostly education (with some execution for Very Big Decisions). At the operator end, it’s mostly execution with some education (dojo training to standardized work and participation to kaizen events). The following chart might help:

Middle managers have the toughest challenge with this complex mix. Their responsibility in terms of lean means taking care of both the education system and the execution system. The big risk is to follow the path of least resistance and treat the lean program purely as an execution system, whereas it clearly is an education one.

How to Start

How did the CEO I mentioned handle this challenge? Let’s start with the execution system. The CEO started by defining five operational indicators that related directly to his P&L challenges (the following are an illustration, and not exactly how the company defined its KPIs, but close enough):

- Accidents: he believed strongly that people don’t come to work to get hurt and was his first priority (every accident across the world is reported to him immediately)

- Customer complaints: which reflected how customers felt about the product, and was a strong lever of sales

- On-time-delivery: to measure service to customers, and again a strong lever of sales

- Days of inventory: a direct measure of cash

- Productivity: measured as direct heads per site. There is no really good measure of productivity, so the assumption was that each site had a more or less stable volume and that reducing the direct headcount while improving OTD should mean productivity improvement

On a monthly basis, the head of the lean program would track the historical evolution on each of these indicators against a target curve of reducing by half in eighteen months.

The important point on the execution front is that each plant manager was held directly accountable for the improvement of the plants according to these indicators, whether he or she chose to do lean or not. Every month, the lean office produced Pareto charts corresponding to each showing how plants stood respective to each other on the operational performance.

On the education front, the group lean manager created standard kaizen workshops corresponding to each indicator:

- Safety risk analysis (accidents)

- Quick response quality control from firewalls and red bins (customer complaints)

- Production plan leveling (OTD)

- Pull system and SMED (days of inventory)

- Single-piece-flow layout (productivity)

Each plant has a dedicated, full-time lean manager whose job was to run a program of workshops, at the steady rhythm of one workshop per month (some did more, some did less). The key aspect of the lean manager’s role was that he or she was in no way held accountable for the results on any indicator – this was clearly the plant’s management responsibility. The lean manager’s job was to run enough workshops (and run them well) to educate plant staff to work with operators to achieve the required results.

The trick here is to make sure that the “lean managers” are not implicitly tasked with getting results: their job is education, and they should be good at this, but that’s as far as it goes. Plant managers must achieve results.

The CEO reinforced this by making a commitment to visit every plant (about thirty across five continents) at least once a year. During these gemba visits, the CEO asked the plant manager (and not the lean manager) to show progress. Making sure the program of training was on track in the plant was the job of the Group lean manager, not the concern of the CEO.

Gemba Walking

The other specificity of this program was the CEO’s personal interest in what happened at operator level. During his plant visits, he would walk the gemba and ask to see how the operators were affected by the changes and how involved they were with the improvement actions.

On the other hand, the group stopped all classroom lean training. No one was expected to “talk lean” or to know about lean. Education occurred hands on, through the kaizen workshops, and the plants had to solve specific problems to improve the indicators. Through their gemba visits with the CEO’s sensei, the CEO and the Group lean manager established a list of key generic problems/generic solutions, which were progressively spread across the board.

Not all plants had results. A few never moved at all. A few showed spectacular improvements. But overall, the entire group of plants started moving, proving once more that lean results are obtained by the dynamic of lean, not simply “respecting standards” in a rigid way. The company went through two eighteen months cycles and was sold as it was beginning its third.

If I reflect back on this experience, I would say that you’re moving in the right direction, but beware of doing so without a sensei. Your CEO needs to understand why taking cost of quality as an indicator is a bad mistake as opposed to customer complaints (sales) and ppm (EBIT).

Remember that lean is a practice, not a theory and much lean know-how takes shape in the form of passing on a lean tradition from sensei to deshi. So, with so much at stake, it’s well worth finding a sensei that can help you clarify the high-level principles as well as guide you in the nuts-and-bolts specifics. If your CEO is not personally driving your efforts on the shop floor, it’s unlikely that a more KPI-focused program will have better results than the previous one.