Make-to-order, very high variety and custom-product situations are often mistakenly considered unsuitable for continuous flow processing and load leveling, since the work content involved in making each different product type varies too much.

In fact, you can approximate continuous flow and achieve many of its benefits in most make-to-order processes, such as in production of custom items, stock picking in warehouses and even administrative (paperwork) processes. This is done by maintaining a First In, First Out (FIFO) flow through the processing steps and carefully regulating the quantity of work you consistently release to that FIFO chain of processing steps.

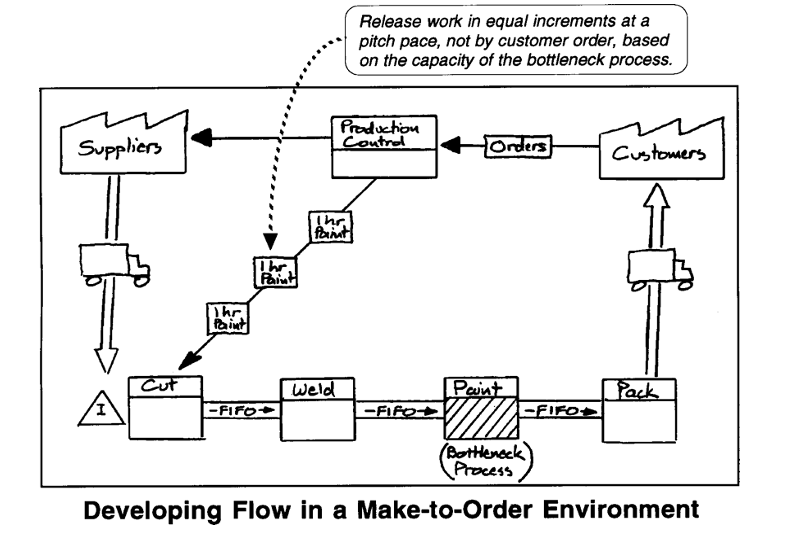

In a make-to-order chain of processes, you typically have to send the schedule or production instruction to the first (leadoff) process. That scheduling information, often called a “traveler,” is then passed from one process on to the next as the material moves forward. Here is the problem: Companies tend to release make- to-order work by customer order. That is, each traveler equals one customer order. If one customer order is large then the traveler has a lot of work in it. If the next customer order is small then the amount of work in that traveler is light.

Unfortunately, this means that travelers, or orders, tend to bunch up excessively between some processing steps. This leads to a loss of FIFO as individual processes select travelers based on setup efficiency and other factors. It is also very difficult to see if you are ahead or behind at any of the processing stages.

Lean relies on fast response to abnormalities so that flow can quickly be re- established, but by the time you notice that a process’s in-box is overflowing, it is too late. The result is an unpredictable and unmanageable flow of work, difficulties in managing capacity, order expediting, peaks and valleys of work volume and late shipments.

You usually can’t hold a supermarket of finished goods to help you level the volume of work in make-to-order production. However, there are three methods you can employ in combination:

- Maintain some inventory of work in the FIFO or sequential-pull queues between processes, especially ahead of the bottleneck The smaller the FIFO lane, the less work on the floor and the shorter the lead time.

- Stop releasing work in increments of customer ordering, and instead release work based on a standard time increment or “pitch.” Do this by determining what is the bottleneck operation in the critical path of your make-to-order process. Then break orders down not by customer, but into equal time increments of work based on the bottleneck capacity.

- Since orders tend to become firm a few days ahead of their shipping date, you can build ahead somewhat when you need to fill slow (This is for volume fluctuations, not for fundamental shifts in demand rate, which require adjusting capacity.) At any given time, you may be working right to customer requirement or slightly ahead. But most importantly, your processes will have steady and thus more manageable work.

Let’s look at an example. If the bottleneck process is painting as shown in the simplified value-stream map below, you might release one hour’s worth of painting work to the FIFO chain of processes once every hour. This means that you need to break each customer order down into one-hour increments of painting work and release one such increment to the value steam once every hour. (Of course, if you can paint one-for-one in line and get rid of the separate batch painting area, all the better. Then there would be a different bottleneck to set the pace for the flow.)

The result is a much more predictable flow that quickly highlights flow-interrupting abnormalities and is very similar to continuous flow processing.

Sometimes a “custom” value stream is not really custom all the way through. The flow may begin with fairly standard components, modules or subassemblies, which are customized after a certain point. Those standard components can often be handled via a supermarket pull system, with FIFO flows or sequential pull used in the custom segment downstream of that supermarket.

Copyright © by Mike Rother

Learning to See Using

Value-Stream Mapping

Develop a blueprint of improvements that will achieve your organization’s strategic objectives.