Many lean practitioners understand standardized work as a reasonably straightforward practice that codifies how specific work processes are completed individually and integrated throughout a value stream. But LEI Senior Advisor John Shook asserts that this practice, when deployed correctly, plays a much more critical role in a lean enterprise.

Sharing his in-depth practical lean management experience as the first American manager at Toyota’s headquarters in Japan and decades of practice after that, he explains how standardized work is crucial to integrating people and process, which is at the heart of lean thinking and practice.

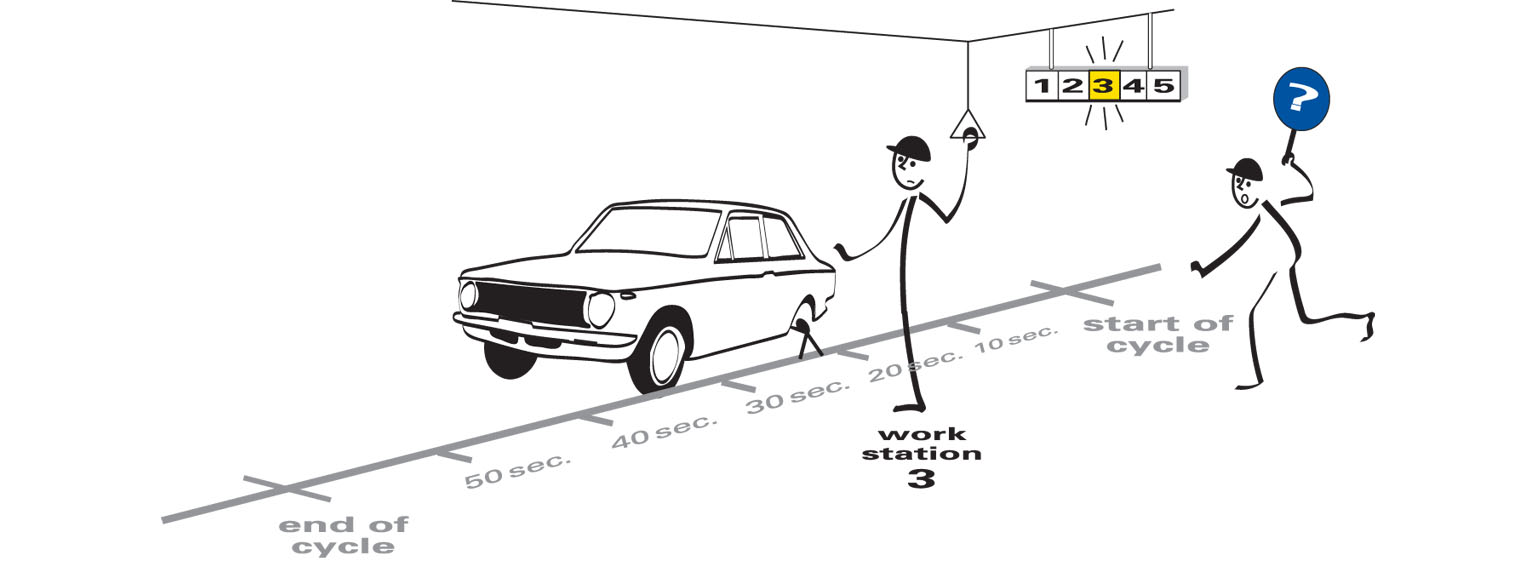

Through the prism of the five neglected, misunderstood, or forgotten aspects of this powerful lean practice, Shook offers a detailed diagnostic that lean practitioners can use to test whether they’re benefiting as fully as possible from this fundamental lean practice. Also, he distills the “Purpose, Process, and People” elements in a handy one-page, quick-reference outline. Finally, he shares an annotated illustration of an example of Toyota’s “Fixed-Position Stop System,” which shows how standardized work integrates people with process into a “socio-technical system on steroids.”

Whether you’re a novice or an advanced lean practitioner, this compilation of Lean Posts will help ensure you fully understand the power — and gain the benefits — of this fundamental lean practice.

Building a Lean Operating and Management System

Gain the in-depth understanding of lean principles, thinking, and practices.

Just downloaded the e-book and a quick read of the first few pages indicates that it’s going to be a useful read. It does, however, prompt me to write a blog article about takt time and why it’s so confusing to many manufacturers. The examples used to illustrate takt time are almost always one fairly narrow case of a product that goes through several steps before completion….like Toyota vehicles! That example isn’t very useful to an operator running a stamping press or an injection molding press putting out dozens to thousands of finished parts every hour for a specific customer who just placed an order to be delivered in two weeks. That’s not to say that the concept of matching production to demand isn’t relevant…it’s to say that the usual example isn’t always very relevant.

You make a very good point; I have used takt time effectively in a high volume level loaded continuous operation but have often wondered how it is best used in lower volume, made to order operations where order types and operational sequencing, etc. change frequently. It seems that that would require a large matrix of takt times for various products and operations which would add to the complexity of the worker on the floor to keep track of and comply with. Any thoughts around how to still keep it simple?

Thanks so much for sending very knowledgeable and informative posts very helpful to me