While Karen Gaudet’s Steady Work aligns with LEI’s goal of supporting humane work in the food and restaurant industry through its Lean-n-Food initiative, there are more basic reasons to read this book. The lessons of a story that lean thinkers John Shook and Scott Heydon call “deeply emotional and imminently practical” are especially relevant today. As hints of (the beginning of) the end of the pandemic emerge, more people are tackling the tough challenges of resuming work as we emerge from an unforeseeable crisis.

Shook and Heydon’s introduction to the book recognizes Karen’s lessons from her work helping transform frontline operations at Starbucks. “It’s the story of a leader helping teams develop steady work to help them get through normal days just a little bit better and help make the worst day ever at work just a little bit bearable,” they say.

Create Standard Work to Free You For Higher Quality

While Steady Work helps you understand practical matters such as the value of standard work, and how to orient managers towards productive questions, there’s more. The book aims high, coaching you in practices both tactical and theoretical, all of which animate a workplace of continuous improvement.

For example, this conversation with Chet Marchwinski explains how—and why—to “create steady work in unsteady times with standardized work sequences.” She explains how Starbucks created “Playbook,” a complete operating system based on the lean principles of delivering more value to customers, consuming fewer resources, and training frontline people to solve problems. She also relates ways that lean principles can help restaurants reconceive service delivery—by reconceiving, say, café locations into pickup or delivery or drive-through.

This book coaches you in practices both tactical and theoretical, helping create a workplace of continuous improvement.

Standardization plays a crucial role in creating steady work, she says, in Standardization Can Set You Free. After Starbucks developed standardized work that helped deliver consistent operations, Karen realized deeper benefits. “The standardization of the work routines and the system level thinking provided us the freedom to focus on connecting with the customers, build greater community supported relationships, look for innovation in the problem-solving process and drive to refine the performance of our team.”

Ask Why–Like You Mean It

One powerful insight from the book relates how Respect for People Means Taking Care with Your Questions. This graceful reflection reveals how hard it is for well-intentioned leaders to shed the habit of “problem-solving” in the guise of asking leading questions, and replace it with a humbler mindset—asking open questions free of opinion. “Thinking your way to the root cause of a problem calls for us to take the journey likely less traveled,” she says. “This takes courage and an ability to openly see all potential causes of a problem to simply want people to align to your opinion or approach assumes a narrow path or that there is one singular way to solve for the problem.”

A related principle of respecting others by respecting them to think is captured in Share Best Thinking Rather than Best Practices. Rolling out a Lean Operating System at Starbucks produced numerous solutions, she relates; but at what cost? “Through rapid deployment of other’s best practices, we rob people of the very thinking needed to build the capability to sustain excellent results.” She distinguishes “Best Practices” from “Best Thinking” and clarifies the value of each, noting that all countermeasures must be considered situationally.

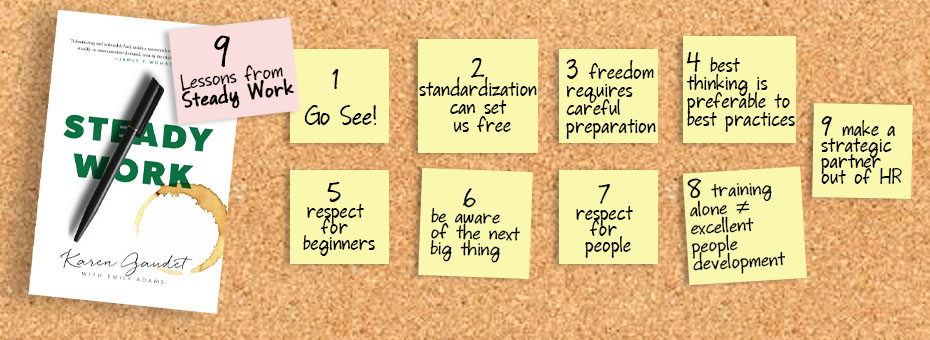

Finally, catch this nice excerpt sharing nine lessons from Steady Work (identified in the banner above.)