As an e-commerce veteran who is versed in lean, I am constantly surprised to discover the relevance of Taichii Ohno’s writing and philosophy in how we work today. Specifically, his insights about designing an “autonomic nervous system” that senses and responds to defects in real time has transformed our industry, just as it has many others. And the potential to help individuals and companies in all sectors remains huge.

In his book Toyota Production System, Ohno defined autonomation as a way of giving a machine intelligence. This systemic awareness is designed in through jidoka, an approach that builds in quality by spotting andIn this technological age, I have found that too many code developers lack quality systems with built-in techniques ensuring they get it right always. correcting defects when they occur, and which relies on error-proofing mechanisms that stop production when standards are not being met. In my field of e-commerce, this has been done through the extensive use of Algorithmic technologies, many of which have replaced human transaction and decision-making dependency.

Indeed, transactions and decisions are being perpetually made now every minute of the day in the background, irrespective of what the humans may be doing in parallel by code. Nothing must necessarily stop for a ‘human touch’ moment. Systems continue to run 24/7, 365 days of a year. While these artificial algorithmic brains run on code and are growing ever more independent, mistakes continue being made—and they are seldom corrected until it’s too late.?

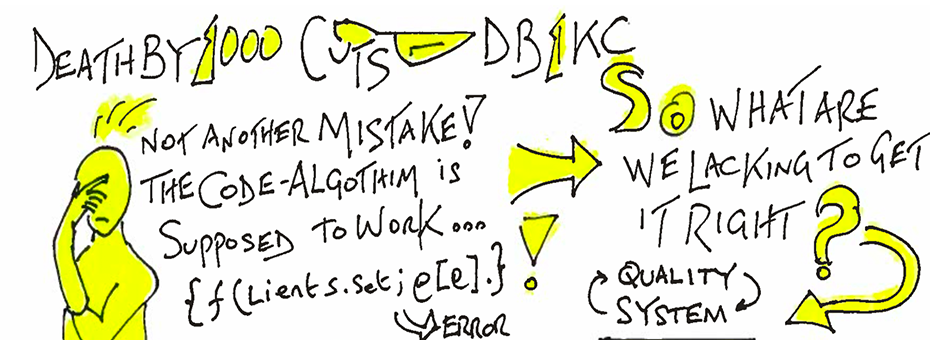

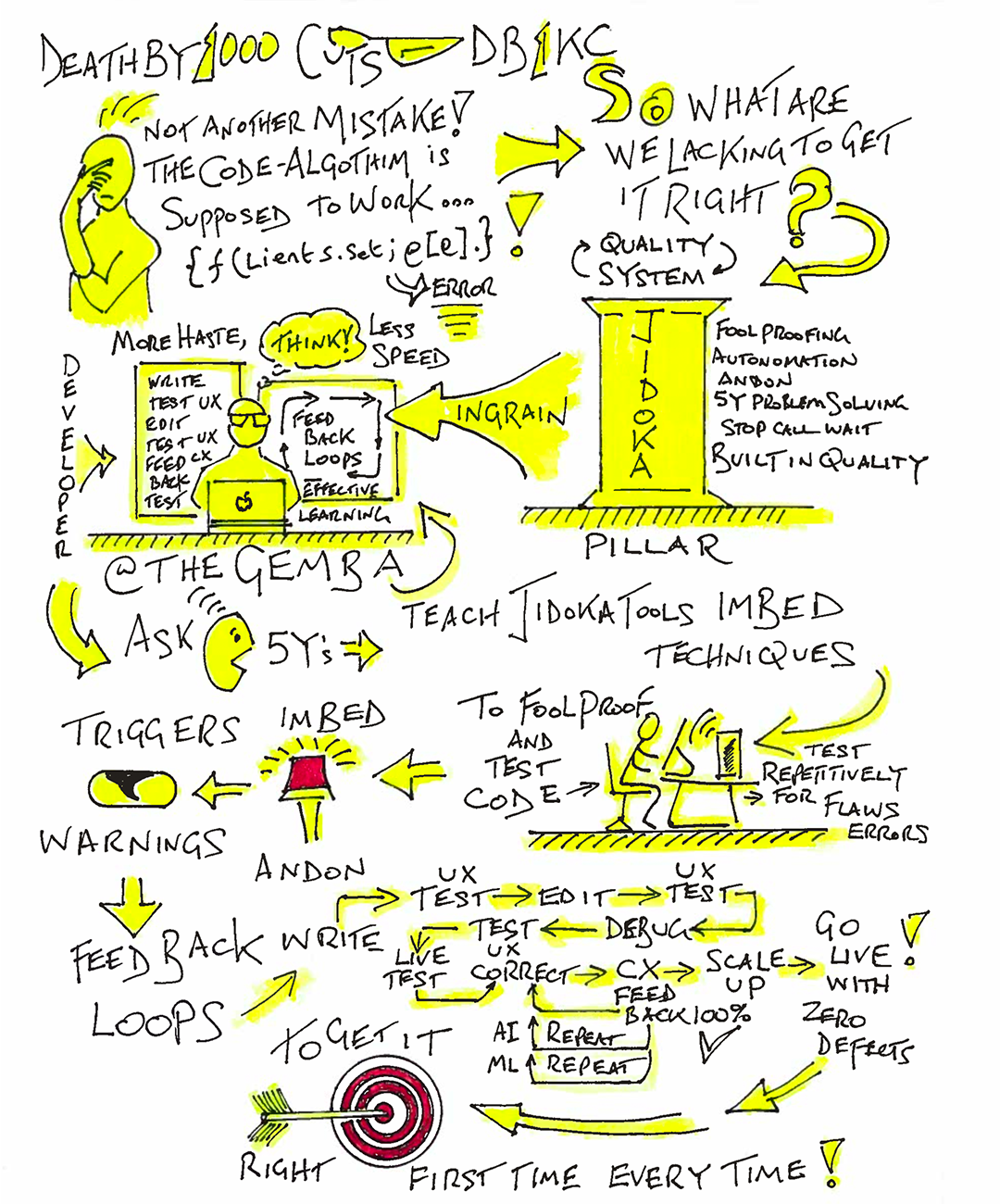

In this technological age, I have found that too many code developers lack quality systems with built–in techniques ensuring they get it right always. They would benefit enormously from tapping into the elements of the Jidoka Pillar of lean/TPS. As we continue to migrate work to the cyber virtual space, the Jidoka principles ensuring quality can help bridge currently open quality gaps. These problems have often been overlooked due to the frenzy for speeding products to market, pressuring people to deliver substandard products NOW and only maybe fix any defects later.

Lean thinkers should apply core lean principles such as 5 why and ‘baka-a-yoke’ (more commonly known as fool proofing by design to prevent mistakes) to the source of code development work—the Gemba. These work methods and principles apply just as powerfully in the digital world as they do when working with a physical device: we are applying the principles and techniques to the actual programming and verifying the programming and actual code to be 100%. This ensures that we are always making a quality decision.

Applying jidoka to daily work offers developers, designers, and creators huge potential and enduring benefits. They can bolster the robustness of system codes and error-proof system codes with the use of feedback loops and correction triggers that is often lacking today. They can build in indicators such as andon warning signals to stop & address problems, fixing abnormalities in the codes being written by people.

I’ve learned from experience the need for tech teams to adopt jidoka as a basic design consideration: getting it 100% right the first time with an effective feedback loop system of warning and correction capabilities.I’m not claiming that this work is simple or easy: few people want to go back and fix flaws detected by the end user, especially the tiny flaws that manifest in code over time through complex applications as they evolve or get modified. These can really stack up and create what I call “death by 1000 cuts.” This human impulse makes sense: developers and designers like to consume their time on creating code as opposed to checking its quality. They want to focus on pushing for innovation breakthroughs and not be stifled by looking back. Rarely is there any mechanism inducing a “go back” check. This ‘I know better’ mindset allows tiny errors and mistakes to accumulate over time, drives up failure costs, and, over time, can tarnish the customer experience and drive repeat customers away. As the saying goes, once bitten twice shy.

I’ve learned from experience the need for tech teams to adopt jidoka as a basic design consideration: getting it 100% right the first time with an effective feedback loop system of warning and correction capabilities. Lean thinkers in this space can remain relevant by tapping autonomation mechanisms, error-proofing, alert warnings that stope and correct. This is more than the introduction of ”tools”: this represents a different way of thinking that rests on feedback loops boosting awareness, testing quality from end to end as a foundation for any system.